One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Email:

info@qingzhou-cable.com

Email:

info@qingzhou-cable.com

Tel:

+8618625503172

Tel:

+8618625503172

Fax:

+8618625503172

Fax:

+8618625503172

Skype:

+8618625503172

Skype:

+8618625503172

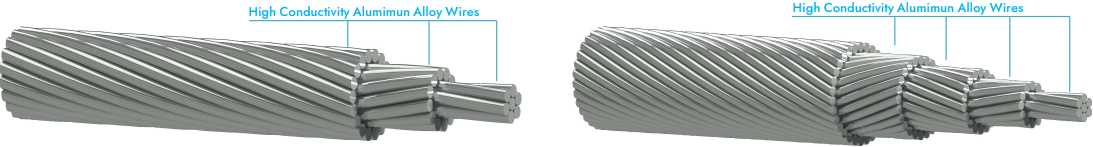

All Aluminium Alloy Conductor according to SS4240814 (AAAC) is an alloyed aluminium conductor that combines good electrical properties with improved mechanical strength. While alloying slightly reduces conductivity, it significantly increases tensile strength, making the conductor more resilient in demanding applications.

Construction

Aluminium Alloy AL59 wires, concentrically stranded. ?Values based on following Specifications:

Swedish Specification SS 424 08 14

Applications

Used as bare overhead conductor for primary and secondary distribution. Designed utilizing a high-Ampacity Aluminium alloy to achieve a high strength-toweight ratio; affords better Power Transfer characteristics. AL-59 Aluminium alloy higher resistance to corrosion than ACSR.

AL-59 Conductor

AL-59 alloy conductors are manufactured from Al-Mg-Si (aluminum-magnesium-silica) rods. The conductor comprises of an inner core and concentrically arranged strands forming the inner and outer layers of the conductor.

ACSR conductors are limited by a maximum current carrying capacity of 838 amperes. The material of construction of AL-59 alloy conductors overcome this limitation enabling AL-59 alloy conductors to transfer up to 1307 amperes of current and evacuate up to 1405 mw of power (56 per cent higher than ACSR Conductors).

Additionally, AL-59 alloy conductors have 9 per cent better 'strength to weight ratio' and 8 per cent lower sag compared with ACSR conductors which enables effective optimization of tower designs and future proofing of the grid.

In view of development of new power transmission and distribution grids by global power incumbents, AL-59 alloy conductors would have a special significance while designing transmission line networks, as the properties of these conductors enable superior power evacuation while optimizing the cost of the entire grid.

Construction

Aluminium Alloy AL 57 wires, concentrically stranded. Values based on following Specifications:

Swedish Specification SS 424 08 12

Applications

Used as bare overhead conductor for primary and secondary distribution. Designed utilizing a high-Ampacity Aluminium alloy to achieve a high strength-toweight ratio; affords better Power Transfer characteristics. AL-57 Aluminium alloy higher resistance to corrosion than ACSR.

TECHNICAL SPECIFICATIONS

PROPERTIES | AL59 (ACSR MOOSE EQUIVALENT) | AL59 (ACSR ZEBRA EQUIVALENT) | AL59 (ACSR PANTHER EQUIVALENT) | |||

Typical factors | 3.50 mm | 0.1378 in | 3.18 mm | 0.1252 in | 3.00 mm | 0.1181 in |

Reference specifications | SS 4240814 | SS 4240814 | SS 4240814 | |||

Total cross section area | 587.00 mm2 | 0.9099 in2 | 484.25 mm2 | 0.7506 in2 | 261.5mm2 | 0.4053 in2 |

Conductive wire | Al59 | Al59 | Al59 | |||

Core wire | Al59 | Al59 | Al59 | |||

Conductor diameter | 31.50 mm | 1.2402 in | 28.62 mm | 1.1268 in | 21.00 mm | 0.8268 in |

Weight | 1618 kg/gm | 1087.2 lbs/mile | 1336 kg/km | 897.8 lbs/mile | 720 kg/km | 483.8 lbs/mile |

Ultimate tensile strength | 14350 kg | 31636.3 lbs | 12340 kg | 27205.01 lbs | 6661 kgf | 14684.97 lbs |

DC resistance at 20°C temperature | 0.05 /km | 0.08 ff/mile | 0.06 ff/km | 0.10 ff/mile | 0.11 ff/km | 0.18 ff/mile |

Maximum operating temperature | 95°C | 203°F | 95°C | 203°F | 95°C | 203°F |

Current carrying capacity at maximum operating temperature | 1094 Amp | 958 Amp | 654 Amp | |||

Designation | Equivalent copper area | Stranding and wire diameter | Approx,overall diameter | Total area | Weight | Nominal breaking load | Max. DC Resistance at 20°C |

mm2 | mm2 | No./mm | mm | mm2 | Kg/Km | KN | Ohm/Km |

31 | 18.48 | 7/2.38 | 7.14 | 31.14 | 85 | 7.77 | 0.9430 |

62 | 37.06 | 7/3.37 | 10.11 | 62.44 | 170 | 15.60 | 0.4700 |

99 | 58.93 | 7/4.25 | 12.75 | 99.30 | 271 | 22.80 | 0.2960 |

157 | 94.12 | 19/3.26 | 16.30 | 158.59 | 436 | 39.70 | 0.1860 |

241 | 143.13 | 19/4.02 | 20.10 | 241.16 | 663 | 55.50 | 0.1230 |

329 | 195.87 | 37/3.37 | 23.60 | 330.03 | 910 | 82.50 | 0.0899 |

454 | 269.74 | 61/3.08 | 27.72 | 454.49 | 1260 | 113.00 | 0.0654 |

593 | 352.31 | 61/3.52 | 31.68 | 593.62 | 1640 | 143.00 | 0.0501 |

774 | 459.51 | 61/4.02 | 36.18 | 774.24 | 2140 | 178.00 | 0.0384 |

910 | 540.52 | 61/4.36 | 39.20 | 910.74 | 2520 | 209.00 | 0.0326 |

Designation | Equivalent copper area | Stranding and wire diameter | Approx,overal | Total area | Weight | Nominal breaking load | Max. DC Resistance |

mm2 | mm2 | No./mm | mm | mm2 | Kg/Km | KN | Ohm/Km |

31 | 17.90 | 7/2.38 | 7.14 | 31.14 | 85 | 9.31 | 0.9740 |

62 | 35.88 | 7/3.37 | 10.11 | 62.44 | 170 | 17.20 | 0.4860 |

99 | 57.07 | 7/4.25 | 12.75 | 99.30 | 271 | 25.30 | 0.3050 |

157 | 91.14 | 19/3.26 | 16.30 | 158.59 | 436 | 43.70 | 0.1930 |

241 | 138.59 | 19/4.02 | 20.10 | 241.16 | 663 | 61.60 | 0.1270 |

329 | 189.67 | 37/3.37 | 23.60 | 330.03 | 910 | 90.70 | 0.0928 |

454 | 261.20 | 61/3.08 | 27.72 | 454.49 | 1260 | 125.16 | 0.0675 |

593 | 341.15 | 61/3.52 | 31.68 | 593.62 | 1640 | 157.00 | 0.0517 |

774 | 444.96 | 61/4.02 | 36.18 | 774.24 | 2140 | 197.00 | 0.0396 |

910 | 523.40 | 61/4.36 | 39.20 | 910.74 | 2520 | 232.00 | 0.0337 |

*Describe Your Buying Requirements in Detail