One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Email:

info@qingzhou-cable.com

Email:

info@qingzhou-cable.com

Tel:

+8618625503172

Tel:

+8618625503172

Fax:

+8618625503172

Fax:

+8618625503172

Skype:

+8618625503172

Skype:

+8618625503172

Annealed copper conductors

Hard drawn copper conductor

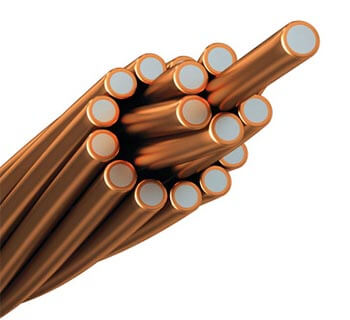

Annealed tinned copper conductor

Annealed copper wire is a durable and reliable grounding conductor designed for direct burial in the ground.

Thanks to copper’s excellent conductivity and the annealed process, the wire offers both flexibility and strength, making installation easier while ensuring long-lasting performance.

Our copper wire can be supplied with varying levels of recycled content – tailored to your project’s environmental goals. To suit different project requirements, it is available in practical packaging options – supplied either on drums for larger installations or on coils for easier handling in smaller projects. An efficient and dependable solution for professional grounding applications.

Hard copper wire is a robust and durable grounding conductor, specifically designed for direct burial in the ground.

With excellent conductivity and a hardened structure, it provides a long-lasting and stable solution for demanding grounding applications. Easy to handle and install, it ensures reliable performance for years to come.

Our copper wire can be supplied with varying levels of recycled content – tailored to your project’s environmental goals. To accommodate various project requirements, the hard copper wire is available in flexible packaging options – supplied either on drums for large-scale installations or on coils for smaller tasks.

Annealed tinned copper wire is a premium-quality grounding conductor, offering enhanced corrosion resistance thanks to its tin coating. The annealed design provides flexibility for easier installation, while copper’s excellent conductivity ensures reliable and efficient performance.

Specifically developed for power distribution systems, this wire is suitable for fixed installations both indoors and outdoors, whether in air or directly underground.

A professional-grade solution that combines durability, safety, and ease of use. Our copper wire can be supplied with varying levels of recycled content – tailored to your project’s environmental goals.

Application: Annealed and Hard Drawn Bare copper conductors.

Suitability: For use in electrical grounding systems and on insulators for overhead line transmission and distribution. Can be used as an earthing cable and in lightning protection systems.

Standards & Voltage Rating: Annealed: EN 13602 and EN 60228. Hard Drawn: BS7884.

Construction: Class 2 annealed stranded copper or Circular non-compacted hard drawn copper conductor.

Details: Offers natural resistance against environmental stresses such as wet, humid, and saline climates.

HNQZ Cable supplies a range of bare copper conductors, which are ideally suited for use in electrical grounding systems and on insulators for overhead line transmission and distribution.

Our bare copper conductors are principally used in energy transmission installations to maximise thermal and electrical conductivity, and to transmit energy with optimal efficiency. This uninsulated wire can be used as an earthing cable and in lightning protection systems. The copper also offers natural resistance against environmental stresses such as wet, humid, and saline climates.

With options for Annealed Stranded Copper, or Hard-Drawn Copper (stranded), it can balance the need for flexibility in an installation design. Our Annealed Stranded Class 2 stranded bare copper wire offers greater flexibility than the stranded hard-drawn wire; whilst this in turn offers more flexibility than a solid hard-drawn copper conductor.

The Annealed stranded bare copper wire is manufactured in accordance with EN 13602 and EN 60228, whilst the hard-drawn stranded bare copper wire is to BS7884.

The Annealed Bare Copper variant is commonly specified to Renewable Energy (including Solar Farms) and Battery Storage projects. The Hard-Drawn variant is more commonly used in the Railways industry.

NOMINAL CROSS SECTIONAL AREA mm2 | NO. OF WIRES | NOMINAL DIAMETER OF WIRES mm | NOMINAL CONDUCTOR DIAMETER mm | NOMINAL WEIGHT kg/km |

16 | 3 | 2.65 | 5.70 | 148.3 |

25 | 7 | 2.10 | 6.30 | 217.3 |

35 | 7 | 2.50 | 7.50 | 308 |

50 | 7 | 3.00 | 9.00 | 444 |

70 | 7 | 3.55 | 10.65 | 621.1 |

95 | 19 | 2.50 | 12.50 | 841 |

120 | 37 | 1.98 | 14.00 | 1055 |

150 | 19 | 3.20 | 16.00 | 1377 |

185 | 37 | 2.50 | 17.50 | 1647 |

240 | 61 | 2.22 | 20.00 | 2070 |

NOMINAL CROSS SECTIONAL AREA mm2 | NO. OF WIRES | DIAMETER OF WIRES mm | DIAMETER OF CONDUCTORS mm | MECHANICAL PROPERTIES OF PLAIN COPPER WIRE | NOMINAL WEIGHT kg/km | MAXIMUM DC RESISTANCE AT 20℃ ohms/km | |

Minimum Elongation % | Minimum Tensile Strength N/mm2 | ||||||

1.5 | 7 | 0.53 | 1.59 | 24 | 200 | 13 | 12.1 |

2.5 | 7 | 0.67 | 2.01 | 24 | 200 | 21 | 7.41 |

4 | 7 | 0.85 | 2.55 | 24 | 200 | 35 | 4.61 |

6 | 7 | 1.05 | 3.15 | 26 | 200 | 52 | 3.08 |

10 | 7 | 1.35 | 3.85 | 26 | 200 | 87 | 1.83 |

16 | 7 | 1.74 | 4.8 | 28 | 200 | 137 | 1.15 |

25 | 7 | 2.19 | 5.8 | 28 | 200 | 215 | 0.727 |

35 | 7 | 2.62 | 6.9 | 28 | 200 | 300 | 0.524 |

50 | 10 | 2.62 | 8.2 | 28 | 200 | 410 | 0.387 |

70 | 14 | 2.62 | 9.7 | 28 | 200 | 595 | 0.268 |

95 | 19 | 2.62 | 11.4 | 28 | 200 | 820 | 0.193 |

120 | 19 | 2.62 | 13.1 | 28 | 200 | 1040 | 0.153 |

150 | 37 | 2.62 | 14.2 | 28 | 200 | 1280 | 0.124 |

185 | 37 | 2.62 | 15.8 | 28 | 200 | 1600 | 0.0991 |

240 | 48 | 2.62 | 18.6 | 28 | 200 | 2100 | 0.0754 |

300 | 61 | 2.62 | 20.4 | 28 | 200 | 2700 | 0.0601 |

400 | 61 | 3 | 26 | 33 | 200 | 3400 | 0.047 |

500 | 61 | 3 | 30 | 33 | 200 | 4400 | 0.0366 |

Area [mm2] | No. of wires | Wire diameter nom. [mm] | Conductor nom. [mm] | Vikt non. [kg/km] | Max resistance [Ω/km] | Standard Length [m] |

16 | 7 | 1,74 | 4,80 | 132 | 1,1500 | - |

16 | 7 | 1,74 | 4,80 | 132 | 1,1500 | 500/K5 |

16 | 7 | 1,74 | 4,80 | 132 | 1,1500 | 1000/K5 |

16 | 7 | 1,74 | 4,80 | 132 | 1,1500 | 2000/K6 |

25 | 7 | 2,14 | 6,00 | 214 | 0,7270 | - |

25 | 7 | 2,14 | 6,00 | 214 | 0,7270 | 500/K5 |

25 | 7 | 2,14 | 6,00 | 214 | 0,7270 | 1000/K6 |

25 | 7 | 2,14 | 6,00 | 214 | 0,7270 | 2000/K10 |

35 | 7 | 2,48 | 7,00 | 295 | 0,5240 | - |

35 | 7 | 2,48 | 7,00 | 295 | 0,5240 | 500/K5 |

35 | 7 | 2,48 | 7,00 | 295 | 0,5240 | 1000/K6 |

35 | 7 | 2,48 | 7,00 | 295 | 0,5240 | 2000/K10 |

50* | 7 | 2,87 | 8,40 | 393 | 0,3870 | - |

50* | 7 | 2,87 | 8,40 | 393 | 0,3870 | 500/K6 |

50* | 7 | 2,87 | 8,40 | 393 | 0,3870 | 1000/K10 |

50* | 7 | 2,87 | 8,40 | 393 | 0,3870 | 2000/K10 |

70 | 19 | 2,14 | 10,70 | 595 | 0,2680 | - |

70 | 19 | 2,14 | 10,70 | 595 | 0,2680 | 500/K10 |

70 | 19 | 2,14 | 10,70 | 595 | 0,2680 | 1000/K10 |

70 | 19 | 2,14 | 10,70 | 595 | 0,2680 | 2000/K12 |

95 | 19 | 2,48 | 12,40 | 818 | 0,1930 | - |

95 | 19 | 2,48 | 12,40 | 818 | 0,1930 | 500/K10 |

95 | 19 | 2,48 | 12,40 | 818 | 0,1930 | 1000/K12 |

95 | 19 | 2,48 | 12,40 | 818 | 0,1930 | 2000/K14 |

Area [mm2] | No. of wires | Wire diameter nom. [mm] | Conductor nom. [mm] | Vikt nom. [kg/km] | Max resistance [Ω/km] | Standard Length [m] |

95 | 37 | 1,80 | 12,60 | 818 | 0,1930 | - |

95 | 37 | 1,80 | 12,60 | 818 | 0,1930 | 500/K10 |

95 | 37 | 1,80 | 12,60 | 818 | 0,1930 | 1000/K12 |

95 | 37 | 1,80 | 12,60 | 818 | 0,1930 | 2000/K14 |

120* | 19 | 2,80 | 14,00 | 1036 | 0,1530 | - |

120* | 19 | 2,80 | 14,00 | 1036 | 0,1530 | 500/K10 |

120* | 19 | 2,80 | 14,00 | 1036 | 0,1530 | 1000/K12 |

120* | 19 | 2,80 | 14,00 | 1036 | 0,1530 | 2000/K14 |

120 | 37 | 2,03 | 14,21 | 1036 | 0,1530 | - |

120 | 37 | 2,03 | 14,21 | 1036 | 0,1530 | 500/K10 |

120 | 37 | 2,03 | 14,21 | 1036 | 0,1530 | 1000/K12 |

120 | 37 | 2,03 | 14,21 | 1036 | 0,1530 | 2000/K14 |

150 | 37 | 2,23 | 15,61 | 1275 | 0,1240 | - |

150 | 37 | 2,23 | 15,61 | 1275 | 0,1240 | 500/K10 |

150 | 37 | 2,23 | 15,61 | 1275 | 0,1240 | 1000/K12 |

150 | 37 | 2,23 | 15,61 | 1275 | 0,1240 | 2000/K16 |

185 | 37 | 2,48 | 17,36 | 1583 | 0,0991 | - |

185 | 37 | 2,48 | 17,36 | 1583 | 0,0991 | 500/K12 |

185 | 37 | 2,48 | 17,36 | 1583 | 0,0991 | 1000/K14 |

185 | 37 | 2,48 | 17,36 | 1583 | 0,0991 | 2000/K20 |

240 | 37 | 2,87 | 20,09 | 2108 | 0,0754 | - |

240 | 37 | 2,87 | 20,09 | 2108 | 0,0754 | 500/K12 |

240 | 37 | 2,87 | 20,09 | 2108 | 0,0754 | 1000/K16 |

240 | 37 | 2,87 | 20,09 | 2108 | 0,0754 | 2000/K22 |

300* | 37 | 3,19 | 22,33 | 2627 | 0,0601 | - |

300* | 37 | 3,19 | 22,33 | 2627 | 0,0601 | 500/K12 |

300* | 37 | 3,19 | 22,33 | 2627 | 0,0601 | 1000/K18 |

300* | 37 | 3,19 | 22,33 | 2627 | 0,0601 | 2000/K24 |

*Describe Your Buying Requirements in Detail