One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Email:

info@qingzhou-cable.com

Email:

info@qingzhou-cable.com

Tel:

+8618625503172

Tel:

+8618625503172

Fax:

+8618625503172

Fax:

+8618625503172

Skype:

+8618625503172

Skype:

+8618625503172

Overhead transmission line

ACSR ACSR/AW HSTACIR/AW STACIR TACSR TACSR/AW FOR SALE

Application:

Power Network

Plant

Railway

Overhead transmission lines are the cables we can see hanging from steel towers to transmit electricity over long-distances from hydro, thermal or nuclear power plants to a substation in suburban areas.

QINGZHOU CABLE manufactures an excellent line of overhead transmission cable products including ACSR/AW with strong corrosion resistance, TACSR with increased current capacity through improved heat resistance, and STACIR to prevent sagging at high temperature using INVAR steel wire with a low expansion coefficient.

Aluminum Cables Steel Reinforced (ACSR)

ACSR is made by stranding aluminum wire around a core zinc coated steel cable.

Although the conductivity of ACSR is lower than that of copper wires, it is lighter and has greater tensile strength due to the steel reinforcement. In high-voltage transmission lines, it produces excellent corona characteristics as the external diameter is larger than hard-drawn copper stranded wire. Suitable for use between major axes, ACSR is mainly used for overhead power transmission lines of more than 154kV.

Aluminum Cables Steel Reinforced/Aluminum Wire (ACSR/AW)

ACSR/AW is made by stranding aluminum wire around a core zinc coated steel cable.

Although the conductivity of ACSR/ AW is lower than that of copper wires, it is lighter and has greater tensile strength due to the steel reinforcement. In high-voltage transmission lines, it produces excellent corona characteristics as the external diameter is larger than hard-drawn copper stranded wire. Suitable for use between major axes, ACSR/AW is mainly used for overhead power transmission lines of more than 154kV. High-strength Super Thermal-resistant Aluminum Alloy Conductor Aluminum-clad Invar

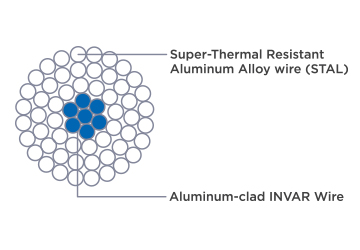

Reinforced/Aluminum Wire (HSTACIR/AW)

HSTACIR/AW is made by stranding super thermal-resistant aluminum alloy around an invar line coated with aluminum of excellent sag properties.

The invar line is a thermally treated alloy line made with a small amount of Zr (zirconium) added to the aluminum. The allowable current is approximately twice higher than general hard-drawn aluminum wires and conductivity is 60%. Stranded with super thermal-resistant alloy on the outside with a zinc-plated invar line in the middle, this product is used on overhead transmission lines that especially require corrosion resistance and prevention of electrolytic corrosion (galvanic corrosion) commonly encountered in coastal areas.

Super Thermal-resistant Aluminum Alloy Conductors Aluminum-clad Invar Reinforced (STACIR)

STACIR is made by stranding super thermal-resistant aluminum alloy around an invar line coated with zinc of excellent sag properties.

The invar line is a thermally treated alloy line made with a small amount of Zr (zirconium) added to the aluminum. The allowable current is approximately twice higher than general hard-drawn aluminum wires and conductivity is 60%. Stranded with super thermal-resistant alloy on the outside with a zinc-plated invar line in the middle, this product can be used in areas where double the capacity of ACSR is necessary without replacing the existing steel towers. In addition, because it is cheaper to install, it is frequently used to replace ACSR.

Thermal-resistant Aluminum Cables Steel Reinforced (TACSR)

TACSR is made by stranding thermal-resistant aluminum wire around a core zinc coated steel cable.

The allowable current is approximately 1.5~1.6 times that of existing ACSR (sending current 50~60% larger than ACSR of the same size). Although the conductivity is approximately 60%, it can be used in high temperatures up to 150°C. TACSR is used in areas where lightweight transmission line operation is necessary.

Thermal-resistant Aluminum Cables Steel Reinforced/ Aluminum Wire (TACSR/AW)

TACSR/ AW is made by stranding thermal-resistant aluminum wire around a core aluminum coated steel cable.

The allowable current is approximately 1.5~1.6 times that of existing ACSR (sending current 50~60% larger than ACSR of the same size). Made with aluminum reinforced steel and thermal resistant aluminum, the corrosion resistance has been significantly improved. Other strengths of TACSR/AW include improved lifespan and lowered electrical resistance.

Aluminum Conductor Steel Reinforced (ACSR)

IEC 61089(A1/S1A)

Nom. Size | Construction | Calculated Aluminum Area |

Approx. Diameter |

Standard Weight | Calculated Breaking Load | Calculated D.C Resistance at 20℃ | Current Carrying Capacity | |

Aluminum | Steel | |||||||

㎟ | Nos./㎜ | ㎟ | ㎜ | ㎏/㎞ | kN | Ϊ/㎞ | A | |

16 | 6/1.84 | 1/1.84 | 16.0 | 5.53 | 64.6 | 60.8 | 1.7934 | 100 |

25 | 6/2.30 | 1/2.30 | 25.0 | 6.91 | 100.9 | 9.13 | 1.1478 | 133 |

40 | 6/2.91 | 1/2.91 | 40.0 | 8.74 | 161.5 | 14.40 | 0.7174 | 180 |

63 | 6/3.66 | 1/3.66 | 63.1 | 11.0 | 254.4 | 21.63 | 0.4555 | 240 |

100 | 6/4.61 | 1/4.61 | 100.1 | 13.8 | 403.8 | 34.33 | 0.2869 | 322 |

125 | 18/2.97 | 1/2.97 | 124.7 | 14.9 | 397.9 | 29.17 | 0.2304 | 381 |

125 | 26/2.47 | 7/192 | 124.6 | 15.7 | 503.9 | 45.69 | 0.2310 | 387 |

160 | 18/3.36 | 1/3.36 | 159.6 | 16.8 | 509.3 | 36.18 | 0.1800 | 446 |

160 | 26/2.80 | 7/2.28 | 160.1 | 17.7 | 644.9 | 57.69 | 0.1805 | 452 |

200 | 18/3.76 | 1/3.76 | 199.9 | 18.8 | 636.7 | 44.22 | 0.1440 | 515 |

200 | 26/3.13 | 7/2.43 | 200.1 | 19.8 | 806.2 | 70.13 | 0.1444 | 522 |

250 | 22/3.08 | 7/2.11 | 249.5 | 21.6 | 880.6 | 68.72 | 0.1154 | 598 |

250 | 26/3.50 | 7/2.72 | 250.1 | 22.2 | 1,007.7 | 87.67 | 0.1155 | 602 |

315 | 45/2.99 | 7/1.99 | 316.0 | 23.9 | 1,039.6 | 79.03 | 0.0917 | 689 |

315 | 26/3.93 | 7/3.05 | 315.4 | 24.9 | 1,269.7 | 106.83 | 0.0917 | 698 |

400 | 45/3.36 | 7/2.24 | 399.0 | 26.9 | 1,320.1 | 98.36 | 0.0722 | 790 |

400 | 54/3.07 | 7/3.07 | 399.7 | 27.6 | 1,510.3 | 123.04 | 0.0723 | 797 |

450 | 45/3.57 | 7/2.38 | 450.4 | 28.5 | 1,485.2 | 107.47 | 0.0642 | 851 |

450 | 54/3.26 | 7/3.26 | 450.7 | 29.3 | 1,699.1 | 138.42 | 0.0643 | 859 |

500 | 45/3.76 | 7/2.51 | 499.7 | 30.1 | 1,650.2 | 119.41 | 0.0578 | 911 |

500 | 54/3.43 | 7/3.43 | 499.0 | 30.9 | 1,887.9 | 153.80 | 0.0578 | 919 |

560 | 45/3.98 | 7/2.65 | 559.8 | 31.8 | 1,848.2 | 133.74 | 0.0516 | 978 |

560 | 54/3.63 | 19/2.18 | 558.9 | 32.7 | 2,103.4 | 172.59 | 0.0516 | 988 |

630 | 45/4.22 | 7/2.81 | 629.4 | 33.8 | 2,079.2 | 150.45 | 0.0459 | 1,053 |

630 | 54/3.85 | 19/2.31 | 628.6 | 34.7 | 2,366.3 | 191.77 | 0.0459 | 1,064 |

710 | 45/4.48 | 7/2.99 | 709.3 | 35.9 | 2,343.2 | 169.56 | 0.0407 | 1,135 |

710 | 54/4.09 | 19/2.45 | 709.5 | 36.8 | 2,666.8 | 216.12 | 0.0407 | 1,147 |

800 | 54/4.34 | 19/2.61 | 798.8 | 39.1 | 3,004.9 | 243.52 | 0.0362 | 1,235 |

ASTM B 232

Code Name |

Nom. Size | Construction | Calculated Aluminum Area |

Approx. Diameter |

Standard Weight | Calculated Breaking Load | Calculated D.C Resistance at 20℃ | Current Carrying Capacity | |

Aluminum | Steel | ||||||||

- | AWG/MCM | Nos./㎜ | ㎟ | ㎜ | ㎏/㎞ | kgf | Ϊ/㎞ | A | |

Turkey | 6 | 6/1.679 | 1/1.679 | 13.28 | 5.04 | 53.67 | 539.94 | 2.1595 | 89 |

Swan | 4 | 6/2.118 | 1/2.118 | 21.14 | 6.35 | 85.41 | 844.71 | 1.3571 | 120 |

Sparrow | 2 | 6/2.672 | 1/2.672 | 33.64 | 8.02 | 135.93 | 1,291.73 | 0.8527 | 161 |

Robin | 1 | 6/3.000 | 1/3.000 | 42.41 | 9.00 | 171.35 | 1,615.87 | 0.6764 | 186 |

Raven | 1/0 | 6/3.371 | 1/3.371 | 53.55 | 10.11 | 216.35 | 1,984.35 | 0.5357 | 216 |

Quail | 2/0 | 6/3.782 | 1/3.782 | 67.40 | 11.35 | 272.33 | 2,400.98 | 0.4256 | 250 |

Pigeon | 3/0 | 6/4.247 | 1/4.247 | 85.00 | 12.74 | 343.41 | 2,994.40 | 0.3375 | 290 |

Penguin | 4/0 | 6/4.770 | 1/4.770 | 107.22 | 14.31 | 433.19 | 3,777.31 | 0.2676 | 337 |

Waxwing | 266.8 | 18/3.091 | 1/3.091 | 135.07 | 15.46 | 430.78 | 3,113.00 | 0.2134 | 400 |

Partridge | 266.8 | 26/2.573 | 7/2.002 | 135.19 | 16.30 | 546.67 | 5,118.90 | 0.2143 | 406 |

Ostrich | 300 | 26/2.728 | 7/2.121 | 151.97 | 17.28 | 614.23 | 5,749.42 | 0.1906 | 437 |

Merlin | 336.4 | 18/3.472 | 1/3.472 | 170.42 | 17.36 | 543.52 | 3,927.72 | 0.1692 | 464 |

Linnet | 336.4 | 26/2.888 | 7/2.245 | 170.32 | 18.29 | 688.31 | 6,393.91 | 0.1701 | 470 |

Oriole | 336.4 | 30/2.690 | 7/2.690 | 170.50 | 18.83 | 784.58 | 7,876.39 | 0.1703 | 474 |

Chikadee | 397.5 | 18/3.774 | 1/3.774 | 201.36 | 18.87 | 642.18 | 4,506.82 | 0.1432 | 516 |

Brant | 397.5 | 24/3.269 | 7/2.179 | 201.43 | 19.61 | 761.98 | 6,630.92 | 0.1438 | 521 |

Ibis | 397.5 | 26/3.139 | 7/2.441 | 201.21 | 19.88 | 813.34 | 7,384.19 | 0.1440 | 523 |

Lark | 397.5 | 30/2.924 | 7/2.924 | 201.45 | 20.47 | 927.02 | 9,249.01 | 0.1442 | 527 |

Pelican | 477.0 | 18/4.135 | 1/4.135 | 241.72 | 20.68 | 770.91 | 5,318.59 | 0.1193 | 580 |

Flicker | 477.0 | 24/3.581 | 7/2.388 | 241.72 | 21.49 | 914.59 | 7,799.74 | 0.1199 | 586 |

Hawk | 477.0 | 26/3.439 | 7/2.675 | 241.51 | 21.78 | 976.40 | 8,865.69 | 0.1200 | 588 |

Hen | 477.0 | 30/3.203 | 7/3.203 | 241.73 | 22.42 | 1,112.37 | 10,785.80 | 0.1201 | 592 |

Osprey | 556.5 | 18/4.465 | 1/4.465 | 281.84 | 22.33 | 898.87 | 6,201.38 | 0.1023 | 640 |

Parakeet | 556.5 | 24/3.868 | 7/2.578 | 282.02 | 23.21 | 1,066.76 | 8,988.20 | 0.1027 | 646 |

Dove | 556.5 | 26/3.716 | 7/2.891 | 281.98 | 23.54 | 1,140.16 | 10,273.35 | 0.1027 | 649 |

Eagle | 556.5 | 30/3.459 | 7/3.459 | 281.91 | 24.21 | 1,297.28 | 12,578.81 | 0.1030 | 654 |

Peacock | 605.0 | 24/4.034 | 7/2.690 | 306.74 | 24.21 | 1,160.60 | 9,781.27 | 0.0944 | 682 |

Squab | 605.0 | 26/3.874 | 7/3.012 | 306.47 | 24.53 | 1,238.68 | 11,141.36 | 0.0945 | 685 |

Teal | 605.0 | 30/3.607 | 19/2.164 | 306.55 | 25.25 | 1,398.33 | 13,589.86 | 0.0947 | 689 |

Kingbird | 636.0 | 18/4.775 | 1/4.775 | 322.34 | 23.88 | 1,028.02 | 7,092.38 | 0.0894 | 697 |

Rook | 636.0 | 24/4.135 | 7/2.756 | 322.29 | 24.81 | 1,219.12 | 10,273.07 | 0.0899 | 704 |

Grosbeak | 636.0 | 26/3.973 | 7/3.089 | 322.33 | 25.16 | 1,302.81 | 11,407.67 | 0.0899 | 707 |

Egret | 636.0 | 30/3.698 | 19/2.220 | 322.21 | 25.89 | 1,470.50 | 14,295.77 | 0.0901 | 712 |

Flamingo | 666.6 | 24/4.234 | 7/2.822 | 337.91 | 25.40 | 1,278.20 | 10,769.89 | 0.0857 | 726 |

Gannet | 666.6 | 26/4.067 | 7/3.162 | 337.76 | 25.75 | 1,365.16 | 11,953.50 | 0.0858 | 728 |

ASTM B 232

Code Name |

Nom. Size | Construction | Calculated Aluminum Area |

Approx. Diameter |

Standard Weight | Calculated Breaking Load | Calculated D.C Resistance at 20℃ | Current Carrying Capacity | |

Aluminum | Steel | ||||||||

- | AWG/MCM | Nos./㎜ | ㎟ | ㎜ | ㎏/㎞ | kgf | Ϊ/㎞ | A | |

Stilt | 715.5 | 24/4.387 | 7/2.924 | 362.77 | 26.32 | 1,372.25 | 11,562.41 | 0.0799 | 759 |

Starling | 715.5 | 26/4.214 | 7/3.277 | 362.62 | 26.69 | 1,465.83 | 12,836.33 | 0.0799 | 762 |

Redwing | 715.5 | 30/3.922 | 19/2.352 | 362.43 | 27.45 | 1,652.69 | 15,686.33 | 0.0801 | 767 |

Cuckoo | 795.0 | 24/4.623 | 7/3.081 | 402.86 | 27.74 | 1,523.79 | 12,634.33 | 0.0719 | 811 |

Drake | 795.0 | 26/4.442 | 7/3.454 | 402.92 | 28.13 | 1,628.65 | 14,261.54 | 0.0719 | 815 |

Tern | 795.0 | 45/3.376 | 7/2.250 | 402.82 | 27.01 | 1,333.44 | 9,995.01 | 0.0719 | 793 |

Condor | 795.0 | 54/3.081 | 7/3.081 | 402.59 | 27.73 | 1,522.66 | 12,756.23 | 0.0720 | 800 |

Mallard | 795.0 | 30/4.135 | 19/2.482 | 402.87 | 28.95 | 1,838.39 | 17,456.77 | 0.0721 | 820 |

Ruddy | 900.0 | 45/3.592 | 7/2.395 | 456.01 | 28.74 | 1,509.74 | 11,098.94 | 0.0635 | 858 |

Canary | 900.0 | 54/3.279 | 7/3.279 | 456.00 | 29.51 | 1,724.65 | 14,448.47 | 0.0635 | 866 |

Rail | 954.0 | 45/3.698 | 7/2.466 | 483.32 | 29.59 | 1,600.23 | 11,764.77 | 0.0599 | 891 |

Cardinal | 954.0 | 54/3.376 | 7/3.376 | 483.38 | 30.38 | 1,828.20 | 15,315.95 | 0.0599 | 899 |

Ortolan | 1033.5 | 45/3.848 | 7/2.565 | 523.33 | 30.78 | 1,732.45 | 12,540.73 | 0.0554 | 836 |

Curlew | 1033.5 | 54/3.513 | 7/3.513 | 523.41 | 31.62 | 1,979.59 | 16,584.23 | 0.0553 | 946 |

Bluejay | 1113.0 | 45/3.995 | 7/2.664 | 564.07 | 31.96 | 1,867.58 | 13,520.90 | 0.0514 | 981 |

Finch | 1113.0 | 54/3.647 | 19/2.189 | 564.10 | 32.83 | 2,120.85 | 17,723.45 | 0.0516 | 986 |

Bunting | 1192.5 | 45/4.135 | 7/2.756 | 604.30 | 33.08 | 2,000.44 | 14,480.00 | 0.0479 | 1,025 |

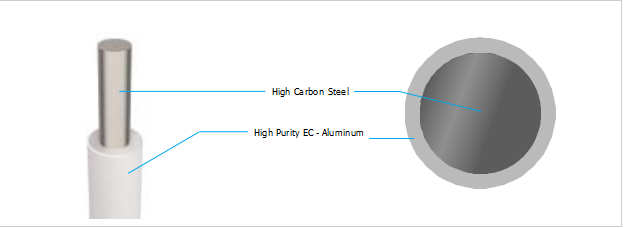

Aluminum Clad Steel Wire (AW)

20.3(%IACS)

Nom. Diameter |

Min. Tensile Strength |

Nom. Weight | Max. D.C Resistance at 20℃ | Min. Thickness of Aluminum | Nom. Cross-Sectional Area |

㎜ | ㎏/㎟ | ㎏/㎞ | Ϊ/㎞ | ㎜ | ㎟ |

2.0 | 137 | 20.71 | 27.0344 | 0.10 | 3.15 |

2.2 | 137 | 25.06 | 22.3425 | 0.11 | 3.81 |

2.4 | 137 | 29.82 | 18.7739 | 0.12 | 4.53 |

2.5 | 137 | 32.35 | 17.3020 | 0.12 | 4.91 |

2.7 | 137 | 37.74 | 14.8337 | 0.13 | 5.73 |

2.9 | 137 | 43.53 | 12.8582 | 0.14 | 6.61 |

3.0 | 137 | 46.59 | 12.0153 | 0.15 | 7.07 |

3.2 | 137 | 53.01 | 10.5603 | 0.16 | 8.05 |

3.3 | 135 | 56.37 | 9.9300 | 0.16 | 8.56 |

3.5 | 135 | 63.41 | 8.8276 | 0.17 | 9.63 |

3.6 | 135 | 67.08 | 8.3440 | 0.18 | 10.18 |

3.8 | 135 | 74.74 | 7.4888 | 0.19 | 11.35 |

4.0 | 135 | 82.82 | 6.7586 | 0.20 | 12.57 |

4.2 | 135 | 91.31 | 6.1303 | 0.21 | 13.86 |

Nom. Diameter |

Min. Tensile Strength |

Nom. Weight | Max. D.C Resistance at 20℃ | Min. Thickness of Aluminum | Nom. Cross-Sectional Area |

㎜ | ㎏/㎟ | ㎏/㎞ | Ϊ/㎞ | ㎜ | ㎟ |

2.0 | 110 | 18.57 | 20.3529 | 0.14 | 3.15 |

2.2 | 110 | 22.47 | 16.7982 | 0.15 | 3.81 |

2.4 | 110 | 26.74 | 14.1152 | 0.16 | 4.53 |

2.5 | 110 | 29.02 | 13.0086 | 0.17 | 4.91 |

2.7 | 110 | 33.84 | 11.1528 | 0.18 | 5.73 |

2.9 | 110 | 39.04 | 9.6675 | 0.20 | 6.61 |

3.0 | 110 | 41.78 | 9.0337 | 0.21 | 7.07 |

3.2 | 110 | 47.54 | 7.9398 | 0.22 | 8.05 |

3.3 | 110 | 50.55 | 7.4659 | 0.23 | 8.56 |

3.5 | 110 | 56.87 | 6.6370 | 0.24 | 9.63 |

3.6 | 110 | 60.16 | 6.2734 | 0.25 | 10.18 |

3.8 | 110 | 67.03 | 5.6305 | 0.26 | 11.35 |

4.0 | 110 | 74.27 | 5.0815 | 0.28 | 12.57 |

4.2 | 110 | 81.88 | 4.6091 | 0.29 | 13.86 |

4.5 | 110 | 94.00 | 4.0150 | 0.30 | 15.91 |

Stranded Aluminum Clad Steel Conductor (AWS)

.png)

ASTM B 416

Nom. Size |

Stranding | Nom. Overall Diameter |

Breaking Load |

Nom. Weight | Max. D.C Resistance at 20℃ | Nom. Cross-Sectional Area |

AWG | Nos./㎜ | ㎜ | kgf | ㎏/㎞ | Ϊ/㎞ | ㎟ |

37/5 | 37/4.620 | 32.36 | 64,770 | 4170 | 0.1394 | 620.6 |

37/6 | 37/4.115 | 28.70 | 54,520 | 3307 | 0.1758 | 492.2 |

37/7 | 37/3.665 | 25.65 | 45,670 | 2622 | 0.2216 | 390.3 |

37/8 | 37/3.264 | 22.83 | 38,190 | 2080 | 0.2794 | 309.5 |

37/9 | 37/2.906 | 20.35 | 30,250 | 1649 | 0.3524 | 245.5 |

37/10 | 37/2.588 | 18.11 | 24,010 | 1308 | 0.4443 | 194.6 |

19/5 | 19/4.620 | 23.11 | 33,270 | 2128 | 0.2699 | 318.7 |

19/6 | 19/4.114 | 20.57 | 27,980 | 1688 | 0.3403 | 252.7 |

19/7 | 19/3.665 | 18.31 | 23,460 | 1339 | 0.4292 | 200.4 |

19/8 | 19/3.264 | 16.31 | 19,610 | 1062 | 0.5411 | 159.0 |

19/9 | 19/2.906 | 14.53 | 15,550 | 842.0 | 0.6821 | 126.1 |

19/10 | 19/2.588 | 12.93 | 12,330 | 667.8 | 0.8603 | 99.93 |

7/5 | 7/4.620 | 13.87 | 12,260 | 781.2 | 0.7428 | 117.4 |

7/6 | 7/4.115 | 12.34 | 10,310 | 619.5 | 0.9197 | 93.09 |

7/7 | 7/3.665 | 11.00 | 8,645 | 491.1 | 1.1598 | 73.87 |

7/8 | 7/3.264 | 9.779 | 7,225 | 389.6 | 1.4627 | 58.56 |

7/9 | 7/2.906 | 8.702 | 5,728 | 308.9 | 1.8442 | 46.44 |

7/10 | 7/2.588 | 7.772 | 4,544 | 245.1 | 2.3255 | 36.82 |

7/11 | 7/2.304 | 6.909 | 3,603 | 194.4 | 2.9325 | 29.18 |

7/12 | 7/2.052 | 6.147 | 2,858 | 154.2 | 3.6976 | 23.16 |

*Describe Your Buying Requirements in Detail