One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Email:

info@qingzhou-cable.com

Email:

info@qingzhou-cable.com

Tel:

+8618625503172

Tel:

+8618625503172

Fax:

+8618625503172

Fax:

+8618625503172

Skype:

+8618625503172

Skype:

+8618625503172

H07ZZ-F Low Smoke Zero Halogen LSZH Rubber

H07RN-F Copper Flexible Rubber Cable

2PNCT/3PNCT-F/R Flexible Rubber Cable

SJ/SJOOW/SJO/Soow Resistance Oil Rubber C

Rubber/PVC Welding Cable

MV Rubber Cable

If you don´t find a suitable cable, we will design it for you acc. to your individual requests.

H07ZZ-F Low Smoke Zero Halogen LSZH Rubbe

Voltage: 450/750V

Conductor: Flexible copper (Class 5)

Insulation: Low Smoke Zero Halogen (LSZH) cross-linked compound Type EI8

Outer Sheath : LSZH cross-linked compound Type EM8The temperature rating of the H07ZZ-F is -5oC to +50oC when flexed and -20oC to +90oC when fixed.

Application: The H07ZZ-F cable is used across a broad range of applications across almost all industry sectors including Airports, Automation & Process Control, Communications & Telecommunication, Marine & Offshore, Oil, Gas & Petrochemicals, Renewable Energy, and Water Treatment.

H07RN-F Copper Flexible Rubber Cable

Voltage: 450/750V

Conductor: Class 5 flexible plain copper to BS EN 60228:2005(previously BS6360)

Insulation: EPR(Ethylene Propylene Rubber) Type E14 to BS7655

Sheath: PCP(Polychioroprene) Type EM3 to BS7655

Sheath Color: Black

Temperature Rating: conductor operation temperature -30°C to +60°C(85°C max)

Minimum Bending Radius: Up to 25mm2:6x

overall diameter: Above to 25mm2:8x

overall diameter Standards: BS7919 CENELEC HD22 4S4.

1.5-2.5mm2 H07RN-Cable | |||

Part No. | Cores x mm2 | Weight kg/km | O/D mm |

57101002 | 2 x 1.0 | 92 | 8.3 |

57101003 | 3 G 1.0 | 111 | 8.9 |

57101004 | 4 G 1.0 | 134 | 9.7 |

57101501 | 1 x 1.5 | 48 | 5.9 |

57101501-IN | 1 x 1.5 | 48 | 5.9 |

57101502 | 2 x 1.5 | 109 | 8.7 |

57101503 | 3 G 1.5 | 137 | 9.7 |

57101504 | 4 G 1.5 | 169 | 10.7 |

57101505 | 5 G 1.5 | 206 | 11.6 |

57101507 | 7 G 1.5 | 371 | 16 |

57101512 | 12 G 1.5 | 546 | 20 |

57101519 | 19 G 1.5 | 777 | 23.5 |

57101527 | 27 G 1.5 | 1090 | 27.5 |

2PNCT/3PNCT-F/R Flexible Rubber Cable

Voltage: 0.6/1kv

Color: Black or by request.

Conductor: Flexible Copper/Tinned Copper

Insulation: Rubber/EPR

Cores: 1,2, 3, 4, 5, 6, 7, 8 Core

Standard: JIS C3327/IEC/VDE etc

Temperature Rating: -25°C to +60°C

Packaging: Iron or Wooden Drum

Application: Indoor Cords for Use in Electrical Appliances of A.C. 600V or Less.

• Handheld and power supply devices according to HD 516/VDE 0298-300

• Lightweight workshop tools that are subject to light loads

• According to HD 516/VDE 0298-300: dry and damp rooms; only temporary use outdoors; not for industrial/commercial or agricultural facilities, except tailors/cutting workshops; not suitable for supplying industrial power tools

• Light & sound technology

| NO.of conductor | Conductor | Insulation thickness (mm) | Sheath thickness (mm) | Overalldiameter (mm) | Max Conductor resistance at 20℃ Ω/KM | ||

| Normal area mm² | Construction(NO./mm) | ||||||

| 1 | 0.75 | 24/0.20 | 0.8 | 0.8 | 4.6±0.2 | 26 | 26.7 |

| 1 | 32/0.20 | 0.8 | 0.8 | 4.8±0.2 | 19.5 | 20 | |

| 1.5 | 30/0.25 | 0.8 | 0.8 | 5.1±0.2 | 13.3 | 13.7 | |

| 2 | 0.75 | 24/0.20 | 0.6 | 0.9 | 6.4±0.2 | 26 | 26.7 |

| 1 | 32/0.20 | 0.6 | 0.9 | 7.0±0.2 | 19.5 | 20 | |

| 1.5 | 30/0.25 | 0.8 | 1 | 8.7±0.2 | 13.3 | 13.7 | |

| 2.5 | 49/0.25 | 0.9 | 1.1 | 10.2±0.3 | 7.98 | 8.21 | |

| 3 | 0.75 | 24/0.20 | 0.6 | 0.9 | 7.0±0.2 | 26 | 26.7 |

| 1 | 32/0.20 | 0.6 | 0.9 | 7.4±0.2 | 19.5 | 20 | |

| 1.5 | 30/0.25 | 0.8 | 1 | 9.1±0.2 | 13.3 | 13.7 | |

| 2.5 | 49/0.25 | 0.9 | 1.1 | 10.8±0.3 | 7.98 | 8.21 | |

| 4 | 56/0.30 | 1 | 1.2 | 13.3±0.4 | 4.95 | 8.09 | |

| 6 | 84/0.30 | 1 | 1.4 | 15.4±0.5 | 3.3 | 3.39 | |

| 4 | 0.75 | 24/0.20 | 0.6 | 0.9 | 7.7±0.2 | 26 | 26.7 |

| 1 | 32/0.20 | 0.6 | 0.9 | 8.0±0.2 | 19.5 | 20 | |

| 1.5 | 30/0.25 | 0.8 | 1 | 10.1±0.3 | 13.3 | 13.7 | |

| 2.5 | 49/0.25 | 0.9 | 1.1 | 12.1±0.4 | 7.98 | 8.21 | |

| 4 | 56/0.30 | 1 | 1.2 | 14.8±0.5 | 4.95 | 8.09 | |

| 6 | 84/0.30 | 1 | 1.4 | 17.1±0.5 | 3.3 | 3.3 | |

SJ/SJOOW/SJO/Soow Resistance Oil Rubber C

1. Insulation: Ethylene Propylene Diene Monomer (EPDM) or EP compound

2. Jacket: rubber or CPE or CP compound

3. Voltage: 300 Volt

4. Temperature Rating:-40ºC to +90ºC

5. 90ºC 300 Volt UL /CSA Portable Cord

6. Resistance Oil Rubber C:Excellent resistance to oil and moisture Good tensile strength, elongation and aging characteristics High flexibility Excellent abrasion resistance Water-resistant UL Listed and CSA Certified for indoor and outdoor use. SJ, SJO, and SJOW have all been superseded by SJOOW. Any SJ, SJO and SJOW RFQs will be quoted as SJOOW Cable

| Part No. | Cable Size | Stranding | OD | Amps | Approx. Lbs./MFT | Package Quantity (in feet) |

| SJOOW103-1000 | 10/3 | 104/30 | 0.61 | 30 | 240 | 1000 |

| SJOOW103-250 | 10/3 | 104/30 | 0.61 | 30 | 240 | 250 |

| SJOOW104-1000 | 10/4 | 104/30 | 0.655 | 25 | 325 | 1000 |

| SJOOW104-250 | 10/4 | 104/30 | 0.655 | 25 | 325 | 250 |

| SJOOW122-1000 | 12/2 | 65/30 | 0.41 | 25 | 105 | 1000 |

| SJOOW122-250 | 12/2 | 65/30 | 0.41 | 25 | 105 | 250 |

| SJOOW123-1000 | 12/3 | 65/30 | 0.43 | 25 | 140 | 1000 |

| SJOOW123-250 | 12/3 | 65/30 | 0.43 | 25 | 140 | 250 |

| SJOOW124-1000 | 12/4 | 65/30 | 0.475 | 20 | 190 | 1000 |

| SJOOW124-250 | 12/4 | 65/30 | 0.475 | 20 | 190 | 250 |

| SJOOW142-1000 | 14/2 | 41/30 | 0.34 | 18 | 75 | 1000 |

| SJOOW142-250 | 14/2 | 41/30 | 0.34 | 18 | 75 | 250 |

| SJOOW143-1000 | 14/3 | 41/30 | 0.365 | 18 | 105 | 1000 |

| SJOOW143-250 | 14/3 | 41/30 | 0.365 | 18 | 105 | 250 |

| SJOOW144-1000 | 14/4 | 41/30 | 0.415 | 15 | 125 | 1000 |

| SJOOW144-250 | 14/4 | 41/30 | 0.415 | 15 | 125 | 250 |

Rubber/PVC Welding Cable

Application:

These cables are used as a connection to welding robots in the automotive industry, shipyards and for manually / automatically

operated lines and spot welding. The robust cable structure makes them resistant to low and high temperatures, ozone and

radiation, oils, acids, fats and petrols.

Standard: BS EN 50525-2-81

Construction:

Conductor: Generally to Class 6 flexible copper conductor according to BS EN 60228 (previously BS 6360)

Separator: PET (Polyester Tape)

Sheath: Rubber compound, Type EM5 according to BS EN 50363

Technical Data

Operating Voltage: 1000V

Operation Temperature: –40°C to + 85°C

Bending Radius: 6x overall diameter

Special Version Upon request

Color Codes: RD-RED Color Codes; E-Black Color Codes

| Construction | Conductor Resistance | Current Carrying Capacity | Operating Capacity | |

|---|---|---|---|---|

| 20℃ | Current Rating For Single Cycle Operatuon Over A Maximum Period Of 5 Minutes (Amps) | |||

| No.xmm2 | Ω/km | 100% | 85% | 60% |

| 10 | ≤1.91 | 100 | 103 | 108 |

| 16 | ≤1.21 | 135 | 145 | 175 |

| 25 | ≤0.78 | 180 | 195 | 230 |

| 35 | ≤0.554 | 225 | 245 | 290 |

| 50 | ≤0.386 | 285 | 305 | 365 |

| 70 | ≤0.272 | 355 | 385 | 460 |

| 95 | ≤0.206 | 430 | 470 | 560 |

| 120 | ≤0.161 | 500 | 540 | 650 |

| 150 | ≤0.129 | 580 | 630 | 750 |

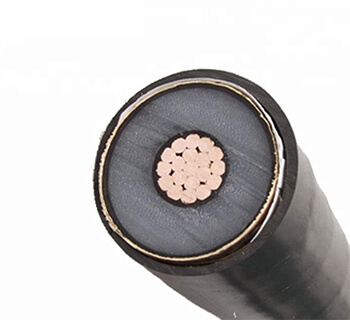

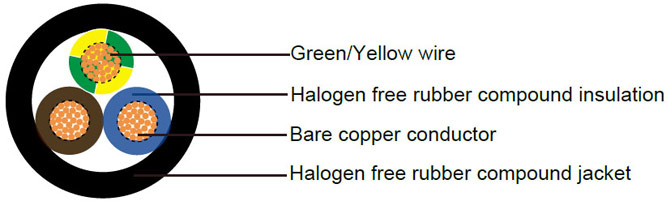

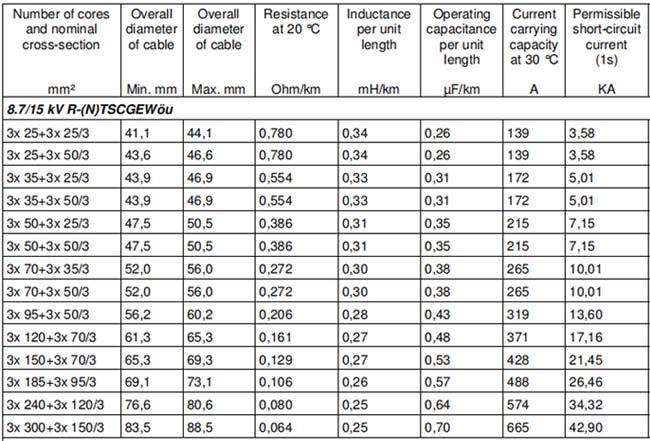

MV Rubber Cable

Rated Voltage:1.8/3KV,3.6/6KV,6/10KV,12/20KV,18/30KV

Conductor: Electrolytic copper tinned, compound type: special compound

Core identification: Natural colouring with black semiconductive ruber on which white digits 1 to 3 are printed.

Core Arrangement: Three man conductor laid-up, with protective-earth conductor split into 3 in the outer interstices.

Inner sheath: Basic material: EPR, compound type: special compound.

Anti-torsion braid:Braid of polyester threads in a vulcanized bond between inner and outer sheath.

Outer sheath:Basic material:CR,compound type: special compound.

Colour: red.

Insulation: EPR

*Describe Your Buying Requirements in Detail