One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Email:

info@qingzhou-cable.com

Email:

info@qingzhou-cable.com

Tel:

+8618625503172

Tel:

+8618625503172

Fax:

+8618625503172

Fax:

+8618625503172

Skype:

+8618625503172

Skype:

+8618625503172

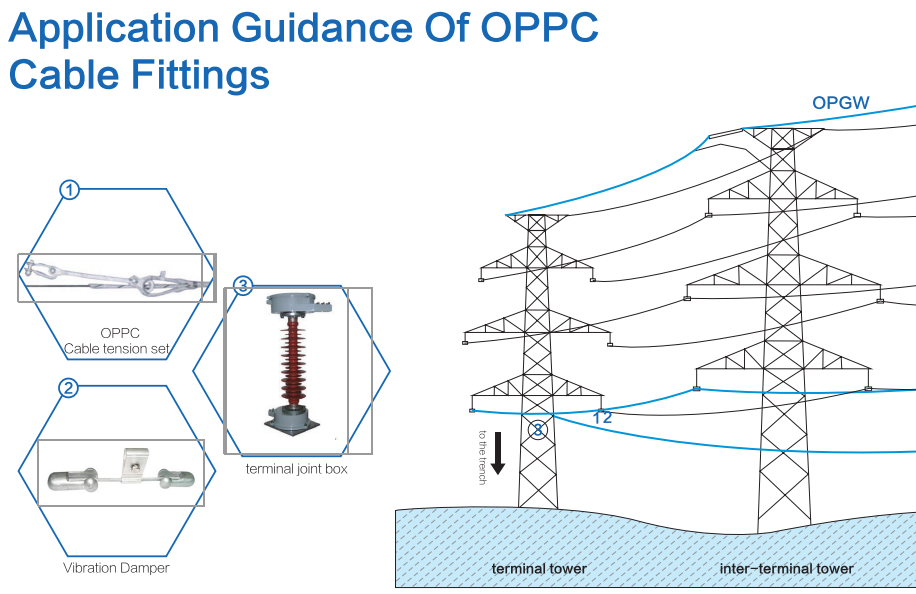

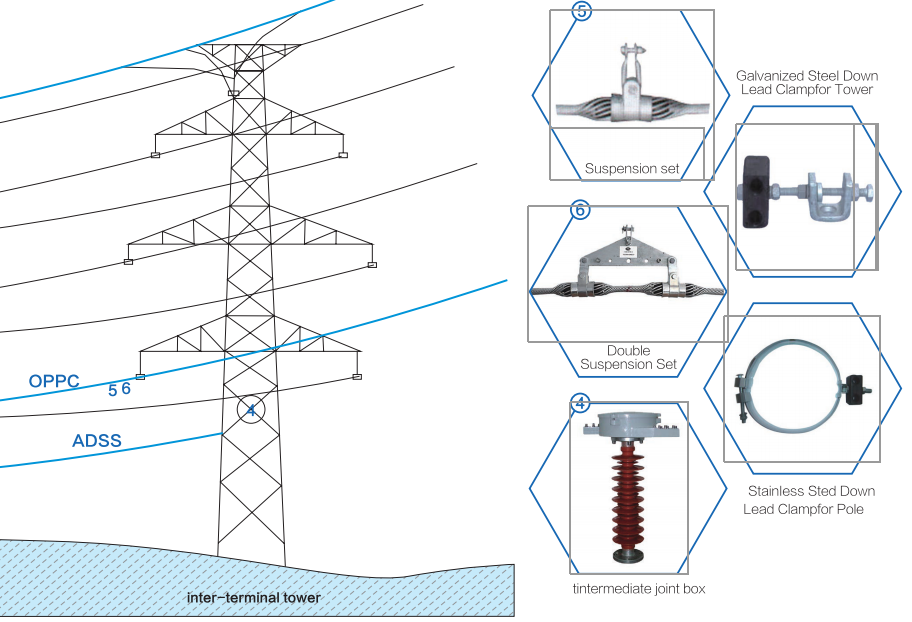

Application Guidance Of OPPC Cable Fittings

1. Preparations before the construction of OPPC

1.1 Data preparation: related data path diagram (voltage, conductor, earth wire, insulator, tower parameter) of this transmission line, the tower line span list and local hydrological and meteorological conditions.

1.2 Confirmation of the construction plan: the construction unit draws up the construction plan (or the operation instruction, OPPC construction schedule) according to the general situation of the project, routing situation, structural parameters of OPPC, etc.,

1.3 Preparation of installation tools: our company will provide a list of construction tools according to the routing situation.

1.4 Field test and acceptance of OPPC and fittings: it should be carried out under the participation of the owner, construction supervisor, constructors, and representatives of the factory, and the model and quantity of OPPC and fittings should be checked.

1.5 Opening test of OPPC: use the optical time domain reflectometer (OTDR) to test the fiber, and record and save the test parameters.

1.6 Construction technology training: the construction operator and the test personnel should be effectively trained by the technique personnel or the construction supervisor, and on site operation demonstration, and discussion of construction scheme under special conditions are necessary.

2. Traction of the construction and engineering control of OPPC

2.1 Installation method of OPPC: tension stringing method is recommended to make the OPPC be subjected to a constant tension during the whole stringing process.

2.2 Traction and control of OPPC: A, select the hauling rope that matches with the cable diameter; B, construction tension is generally controlled within 10%RTS, and not more than 20%RTS at most; C, the initial stringing speed is 5m/min, after passing the tower, it can move 30m/min at a constant speed, and not more than 40m/min at most; D, prevent the optical cable from jumping out of the groove, the pulley should be deflected at a proper angle and paid attention to by a special personnel; E, after releasing the optical cable, the reserved length of the optical cable on the tower should meet the requirement of the connection (about 10 meters).

2.3 Straining and hanging of OPPC: A, straining tension should be less than 20%RTS; B, instead of straining from two ends to the middle, it should be strained from one direction during straining; C, when using straining tools, they should clamp at the tail of the optical cable, and make sure the tools do not hurt the fiber; D, when adjusting the tension sag, the straining preformed armor rod must be used as the straining tool of the optical cable; E, the sag of the throughHype tension tower generally should be adjusted to 2m to 3m.

3. Installation of fittings accessories

3.1 Installation of tension fittings should be operated under instructions.

3.2 Installation of suspension fittings should be operated under instructions.

3.3 Installation of lightning protection damper should be operated under instructions.

4. Connection and test of fiber

4.1 Intermediate joint box: choose different fixing methods according to the type of the tension tower, and execute the plan as scheduled.

4.2 Terminal joint box: it is divided into two steps, installation of the lower joint box and the top joint box, and execute the plan as scheduled.

4.3 Test in the whole process: after the construction of the optical cable, bidirectional whole range test should be carried out, including unidirectional fiber welding loss and bidirectional average loss.

4.4 Complete the record of the cable line disks and the fiber loss test.

5. Quality control and matters needing attention in construction. Strictly follow the requirements of the work instruction

6. Daily operation and maintenance of OPPC

OPPC should be operated and managed jointly by the transmission line department, communication and relay protection department. The photoelectric separation of OPPC happens at the terminal joint box which is generally regarded as the cut-off point of operation management and maintenance.

7. Filing process

Execute in accordance with the regulations of engineering management.

*Describe Your Buying Requirements in Detail