One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Email:

info@qingzhou-cable.com

Email:

info@qingzhou-cable.com

Tel:

+8618625503172

Tel:

+8618625503172

Fax:

+8618625503172

Fax:

+8618625503172

Skype:

+8618625503172

Skype:

+8618625503172

GTACSR, GZTACSR used for overhead power transmission line.

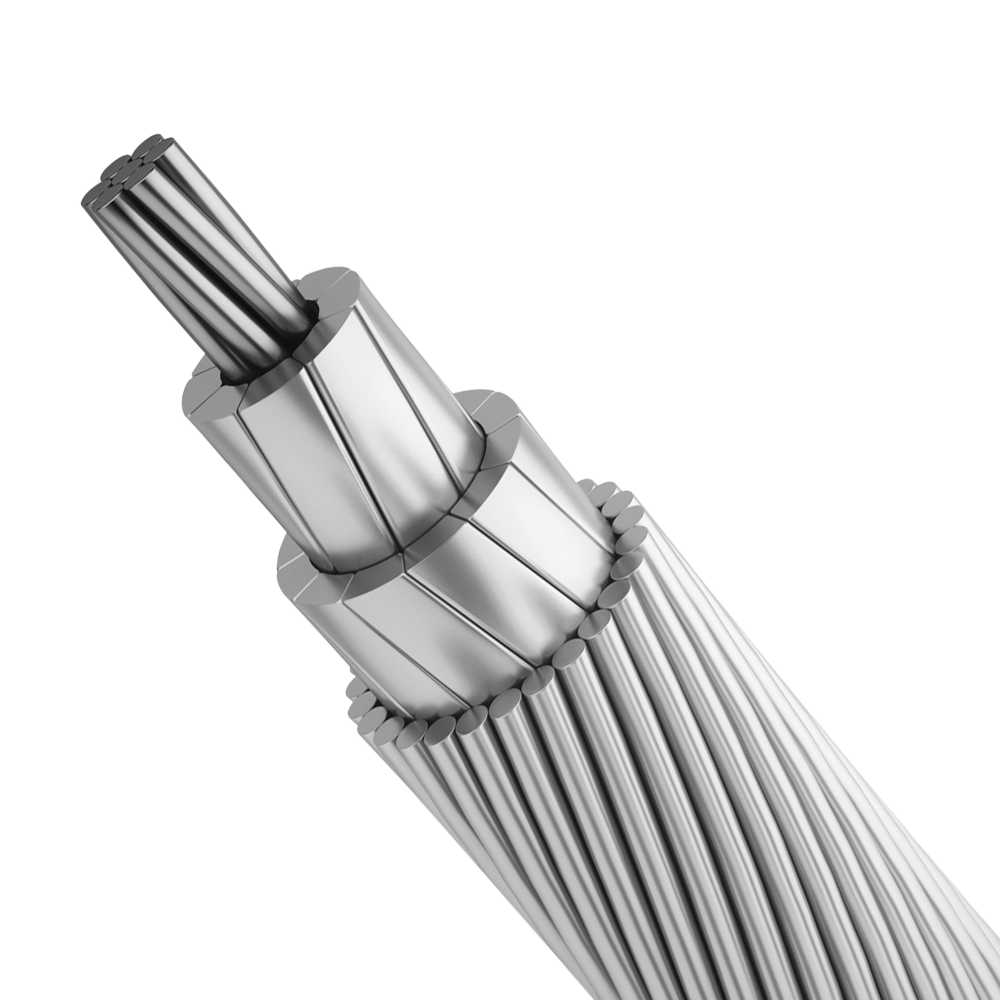

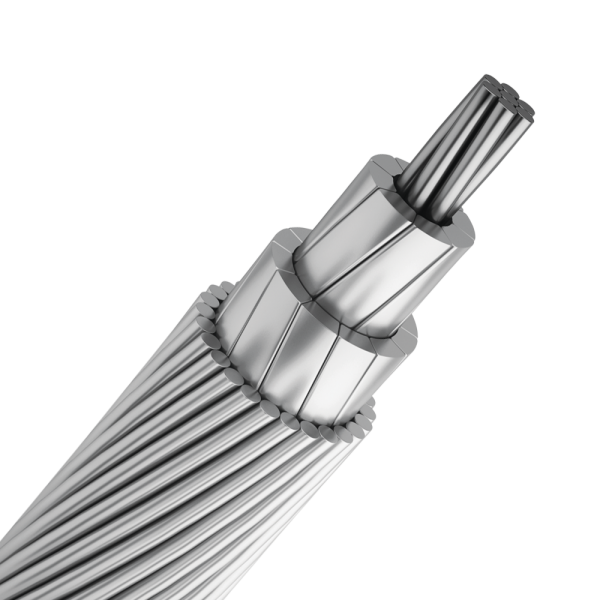

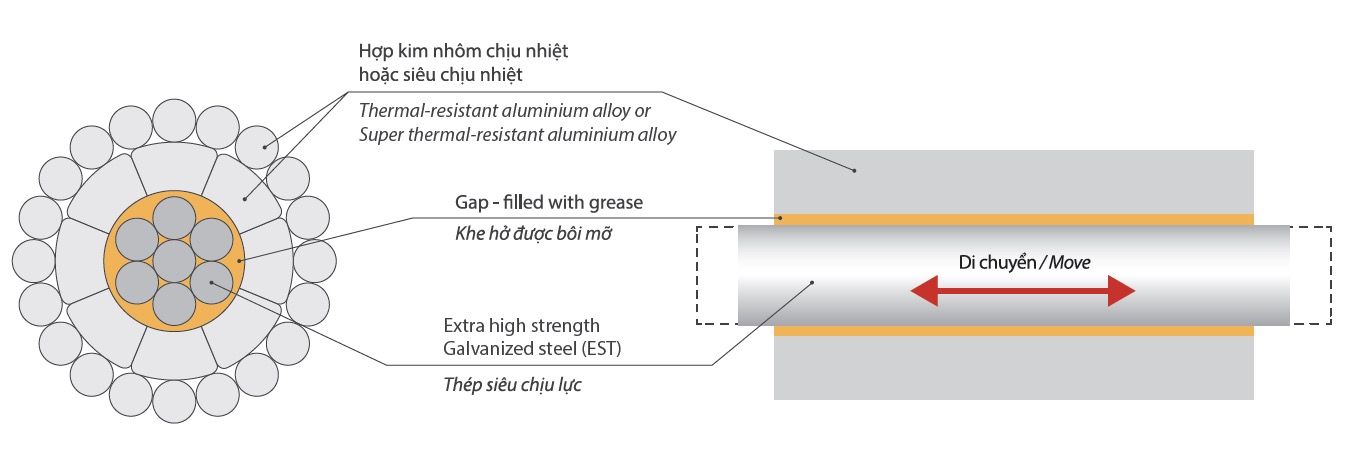

Gap type conductor

APPLICATION:

GTACSR, GZTACSR used for overhead power transmission line.

Standard: IEC 62420, IEC 62219, IEC 60888, IEC 62004

Construction:

- The center is extra high strength galvanized steel, the outer layer is thermal-resistant (or super thermal-resistant) aluminum alloy.

- To create a gap between the core and the inner aluminum layer , the inner aluminum layer has a trapezoid shape.

- A gap between layers of aluminum alloy and steel core is filled with heat-resistant grease to prevent friction between the steel core and aluminum parts.

- The layers of aluminum alloy and steel core can move independently.

Characteristics:

Max. conductor temperature in normal operation:

GTACSR: 150℃

GZTACSR: 210℃

Advantages:

- GAP type conductors can carry up to 1.6 times (GTACSR) or 2 times (GZTACSR) the current of conventional overhead conductors due to their high temperature capability.

- Gap conductors are an excellent solution for uprating overhead lines. Existing ACSR conductors can easily be replaced by Gap conductors offering up to double the capacity.

- No or limited modifications to towers or structures are required.

GTACSR/GZTACSR can be designed to have the same mechanical characteristics as existing ACSR. Design examples are shown below.

Size | mm2 | 185 | 240 | 265 | 310 | 370 | |

Equivalent conductor | Lynx | Hawk | Hen | Goose | Redwing | ||

Stranding |

(Z)TAI |

No/mm | 14/ TZ*1(3.23) 10/TZ(2.98) | 15/ TZ(3.46) 10/TZ(3.69) | 19/3.1 10/TZ(3.94) | 16/3.9 10/TZ(3.94) | 17/4.15 12/TZ(3.83) |

Est | 7/2.0 | 7/2.4 | 7/2.8 | 7/2.8 | 7/3.8 | ||

Rated tensile strength | kN | 62.4 | 86.8 | 107.5 | 113.8 | 179.5 | |

Diameter | GTACSR/GZTACSR | mm | 17.8 | 20.6 | 22.6 | 24.4 | 27.3 |

Steel core | 6.0 | 7.2 | 8.4 | 8.4 | 11.4 | ||

Cross sectional area | Aluminum |

mm2 | 184.5 | 247.9 | 265.3 | 313.1 | 368.2 |

Steel core | 21.99 | 31.67 | 43.11 | 43.11 | 79.38 | ||

Total | 206.5 | 279.6 | 308.4 | 356.2 | 447.6 | ||

Weight | Aluminum | kg/km | 700.3 | 955.9 | 1098 | 1227 | 1666 |

D.C.Resistance at 20˚ | C | Ω/km | 0.160 | 0.119 | 0.111 | 0.0941 | 0.0798 |

Current carrying capacity*2 | GTACSR(150˚C) | A | 713 | 863 | 919 | 1021 | 1147 |

GZTACSR(210˚C) | 871 | 1058 | 1128 | 1255 | 1414 | ||

Modulus of elasticity | GTACSR/GZTACSR | GPa | 77.1 | 78.1 | 81.9 | 79.2 | 87.4 |

Steel core | 205.9 | 205.9 | 205.9 | 205.9 | 205.9 | ||

Coefficient of linear expansion | GTACSR |

10-6/˚C | 19.7 | 19.6 | 19.0 | 19.4 | 18.2 |

Steel core | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 | ||

Size | mm2 | 410 | 413 | 520 | 620 | |

Equivalent conductor | Condor | Drake | - | - | ||

Stranding |

(Z)TAI |

No/mm | 15/4.6 10/TZ(4.55) | 16/4.4 10/TZ(4.65) | 18/TZ(4.01) 14/TZ(3.96) 10/TZ(3.88) | 16/TZ(4.80) 12/TZ(4.75) 12/TZ(3.47) |

Est | 7/3.0 | 7/3.2 | 7/3.0 | 7/3.2 | ||

Rated Tensile Strengt | h | kN | 138.1 | 149.2 | 152.9 | 178.3 |

Diameter | GTACSR/GZTACSR | mm | 27.6 | 27.8 | 29.0 | 31.5 |

Steel core | 9.0 | 9.6 | 9.0 | 9.6 | ||

Cross sectional area | Aluminum |

mm2 | 411.9 | 413.2 | 518.0 | 615.7 |

Steel core | 49.48 | 56.29 | 49.48 | 56.29 | ||

Total | 461.4 | 469.5 | 567.5 | 672.0 | ||

Weight | Aluminum | kg/km | 1557 | 1616 | 1856 | 2179 |

D.C.Resistance at 20˚ | C | Ω/km | 0.0714 | 0.0714 | 0.0570 | 0.0478 |

Current carrying capacity*2 | GTACSR(150˚C) | A | 1257 | 1219 | 1356 | 1516 |

GZTACSR(210˚C) | 1500 | 1503 | 1667 | 1866 | ||

Modulus of elasticity | GTACSR/GZTACSR | GPa | 77.3 | 79.1 | 74.4 | 73.5 |

Steel core | 205.9 | 205.9 | 205.9 | 205.9 | ||

Coefficient of linear expansion | GTACSR | 10-6/˚C | 19.7 | 19.4 | 20.2 | 20.3 |

Steel core | 11.5 | 11.5 | 11.5 | 11.5 | ||

*1: TZ: Trapezoid wire

*2: Ambient temp.: 40 degree C, Wind 0.5m/sec, Wind direction: 45degree,

Solar radiation: 0.1W/cm2, Absorptivity & Emmisivity of conductor surface: 0.5

*Describe Your Buying Requirements in Detail