One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Email:

info@qingzhou-cable.com

Email:

info@qingzhou-cable.com

Tel:

+8618625503172

Tel:

+8618625503172

Fax:

+8618625503172

Fax:

+8618625503172

Skype:

+8618625503172

Skype:

+8618625503172

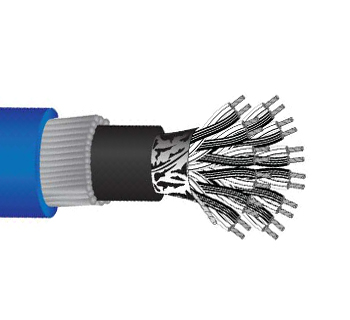

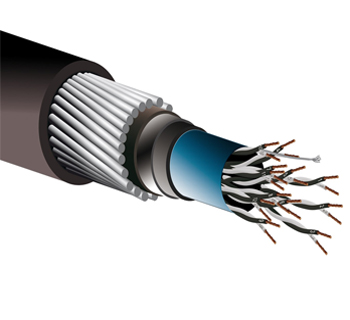

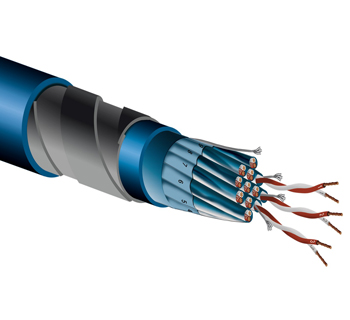

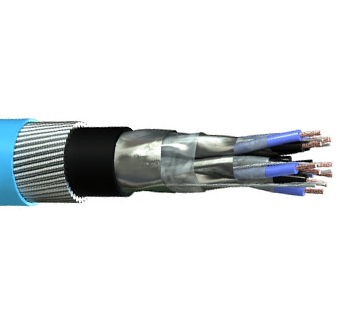

Paired instrumentation, process control and computer systems cable

Quality Instrumentation Cable Supplier & Manufacture in China

APPLICATION

These single pair or triad instrumentation cables are constructed with heat and moisture resistant cross- linked polyethylene (XLPE) with an abrasion, oil, chemical and flame-resistant polyvinyl chloride (PVC), chlorinated polyethylene (CPE) or low smoke, zero halogen (LSZH/XLPO) jacket for use in utility substa- tion or power generation facilities.

They are recomended for indoor or outdoor applica- tions in conduit, duct, cable tray or aerial installations and NEC-compliant for continuous operation at 90°C in wet and dry locations.

CABLE STANDARDS

BS EN 60228, BS 6234, BS 50363;

BS EN/IEC 60332-1, BS EN/IEC 60332-3-24;

BS EN 50288

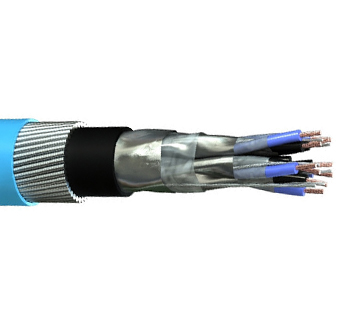

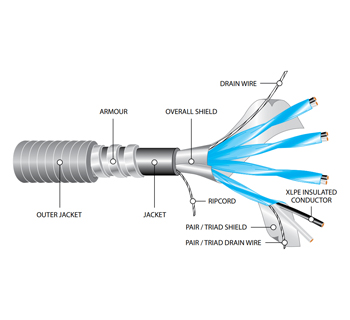

Conductor

Class 1 solid copper conductor

Class 2 stranded copper conductor

Class 5 flexible copper conductor

Insulation

XLPE (Cross-Linked Polyethylene) Type 03

Binder Tape

PET (Polyester Tape)

Screen

AL/PET (Aluminium/Polyester Tape)

Drain Wire

Tinned copper

Bedding

LSZH (Low Smoke Zero Halogen) Type LTS3

Covering

Lead or polyamide

Inner Sheath

LSZH (Low Smoke Zero Halogen) Type LTS3

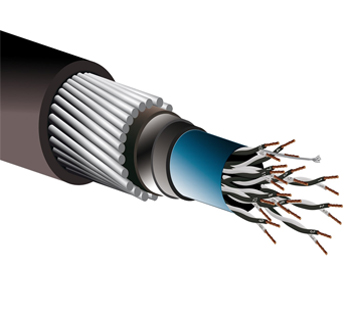

Armour

Galvanized steel wires

Outer Sheath

LSZH (Low Smoke Zero Halogen) Type LTS3

| Conductor | Solid or stranded copper |

| Insulation | Various - to meet the electrical and environmental requirements of the application |

| Screen (cabling elements + cable core) | When required, one of any combination of: - Metal tape - Metal tape laminated to a plastic tape - Plain or coated metal braid - Helical wrap or parallel copper wires - Semi-conducting layer |

| Filling compounds | Water swellable tape, water swellable non-toxic powder or combination of materials are allowed |

| Interstitial fillers | Non-hygroscopic material |

| Moisture barrier | Metallic foil allowed |

| Inner sheath | Materials to meet requirements of EN 50290-2 |

| Metallic protection | One or more of the following: - Galvanised steel wires - Steel or brass tapes - Galvanised steel or tinned copper wire braid |

| Outersheath | As per insulation |

| Conductor | Solid, stranded or flexible plain or metal coated copper (Class 1, 2 or 5)* |

| Insulation | PVC, PE or XLPE |

| Cores | Pair (twisted) triple (twisted) quad (twisted) |

| Twisting | Lay length clearly defined; depending on conductor size and element; between 100 and 150mm |

| Individual pair screens | Laminated tape aluminium/PET total thickness 24µm |

| Drain wire | Solid tinned copper drain wire 0.6mm Ø, under individual screen |

| Collective screen | Collective screen (24µm aluminium/PET) tape + 7 stranded tinned copper drain wire (0.5mm2); overlap of foil min 20%; drain wire in direct contact with metallic side of the foil wrapping layer of tape under collective screen |

| Inner Sheath | PVC, PE or LSZH |

| Metal braid | tinned copper wires (C) wire diameter ≥0.3mm filling factor ≥0.57mm |

| Armouring | SWA, Flat steel wires with counter helix, Steel or Brass Tape |

| OuterSheath | PVC, PE or LSZH |

XLPE - SWA - LSZH Instrumentation Cable

NO. OF PAIRS/TRIPLE | NOMINAL CROSS SECTIONAL AREA mm² | NOMINAL OVERALL DIAMETER mm |

2P | 0.5 | 20 |

2P | 1 | 20.8 |

2P | 1.5 | 22.6 |

2P | 2.5 | 25.3 |

2P | 0.75 | 20.6 |

3P | 0.5 | 21.9 |

3P | 1 | 23.1 |

3P | 1.5 | 25.1 |

3P | 2.5 | 30.1 |

3P | 0.75 | 23.2 |

5P | 0.5 | 23.1 |

5P | 1 | 25.3 |

5P | 1.5 | 28 |

5P | 2.5 | 40.5 |

5P | 0.75 | 25.1 |

10P | 0.5 | 30.2 |

10P | 1 | 32 |

10P | 1.5 | 37.1 |

10P | 2.5 | 45.1 |

10P | 0.75 | 31.8 |

15P | 0.5 | 33.5 |

15P | 1 | 36.9 |

15P | 1.5 | 41.2 |

15P | 2.5 | 51.3 |

15P | 0.75 | 36.7 |

20P | 0.5 | 37.8 |

20P | 1 | 40.3 |

20P | 1.5 | 45.1 |

20P | 2.5 | 58.6 |

20P | 0.75 | 40.1 |

30P | 0.5 | 43 |

30P | 1 | 45.4 |

30P | 1.5 | 53 |

30P | 2.5 | 72.2 |

30P | 0.75 | 45.2 |

Conductor AWG |

Pair/Triad Count | Conductor Strand Class/ Stranding | Nominal Insulation Thickness in (mm) | Nominal Jacket Thickness in (mm) | Nominal Cable O.D. in (mm) | Approximate Cable Weight Lbs/Mft (Kg/Km) |

18 AWG | 1 pair | B / 7 | 0.030 (0.8) | 0.045 (1.1) | 0.320 (8.2) | 49 (73) |

18 AWG | 2 pair | B / 7 | 0.030 (0.8) | 0.045 (1.1) | 0.490 (12.5) | 128 (190) |

18 AWG | 4 pair | B / 7 | 0.030 (0.8) | 0.060 (1.5) | 0.680 (17.3) | 190 (283) |

18 AWG | 8 pair | B / 7 | 0.030 (0.8) | 0.060 (1.5) | 0.810 (20.7) | 332 (494) |

18 AWG | 12 pair | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 0.960 (24.5) | 486 (723) |

18 AWG | 16 pair | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.090 (27.8) | 605 (900) |

18 AWG | 24 pair | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.430 (36.5) | 960 (1428) |

18 AWG | 1 triad | B / 7 | 0.030 (0.8) | 0.045 (1.1) | 0.330 (8.4) | 60 (89) |

18 AWG | 2 triad | B / 7 | 0.030 (0.8) | 0.045 (1.1) | 0.550 (14.0) | 152 (226) |

18 AWG | 4 triad | B / 7 | 0.030 (0.8) | 0.060 (1.5) | 0.720 (18.4) | 261 (388) |

18 AWG | 8 triad | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 0.920 (23.5) | 454 (676) |

18 AWG | 12 triad | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.110 (28.3) | 627 (933) |

18 AWG | 16 triad | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.150 (29.3) | 771 (1147) |

18 AWG | 24 triad | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.530 (39.0) | 1218 (1812) |

16 AWG | 1 pair | B / 7 | 0.030 (0.8) | 0.045 (1.1) | 0.340 (8.7) | 62 (92) |

16 AWG | 2 pair | B / 7 | 0.030 (0.8) | 0.045 (1.1) | 0.540 (13.8) | 153 (228) |

16 AWG | 4 pair | B / 7 | 0.030 (0.8) | 0.060 (1.5) | 0.670 (17.1) | 255 (379) |

16 AWG | 8 pair | B / 7 | 0.030 (0.8) | 0.060 (1.5) | 0.850 (21.7) | 408 (607) |

16 AWG | 12 pair | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.060 (27.0) | 610 (908) |

16 AWG | 16 pair | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.230 (31.4) | 770 (1146) |

16 AWG | 24 pair | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.380 (35.2) | 1175 (1748) |

16 AWG | 1 triad | B / 7 | 0.030 (0.8) | 0.045 (1.1) | 0.370 (9.4) | 78 (116) |

16 AWG | 2 triad | B / 7 | 0.030 (0.8) | 0.060 (1.5) | 0.630 (16.1) | 209 (311) |

16 AWG | 4 triad | B / 7 | 0.030 (0.8) | 0.060 (1.5) | 0.740 (18.9) | 349 (519) |

16 AWG | 8 triad | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.030 (26.3) | 575 (856) |

16 AWG | 12 triad | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.220 (31.1) | 803 (1195) |

16 AWG | 16 triad | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.360 (34.7) | 1010 (1503) |

16 AWG | 24 triad | B / 7 | 0.030 (0.8) | 0.080 (2.0) | 1.590 (40.6) | 1549 (2305) |

*Describe Your Buying Requirements in Detail