One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Email:

info@qingzhou-cable.com

Email:

info@qingzhou-cable.com

Tel:

+8618625503172

Tel:

+8618625503172

Fax:

+8618625503172

Fax:

+8618625503172

Skype:

+8618625503172

Skype:

+8618625503172

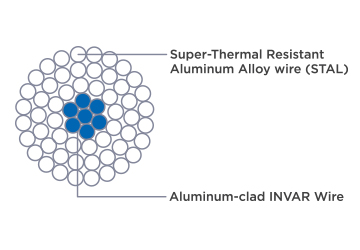

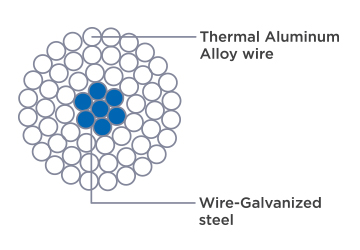

TACSR conductors are recommended for new lines for high power transfer requirements.

AW Type has excellent rustless characteristics

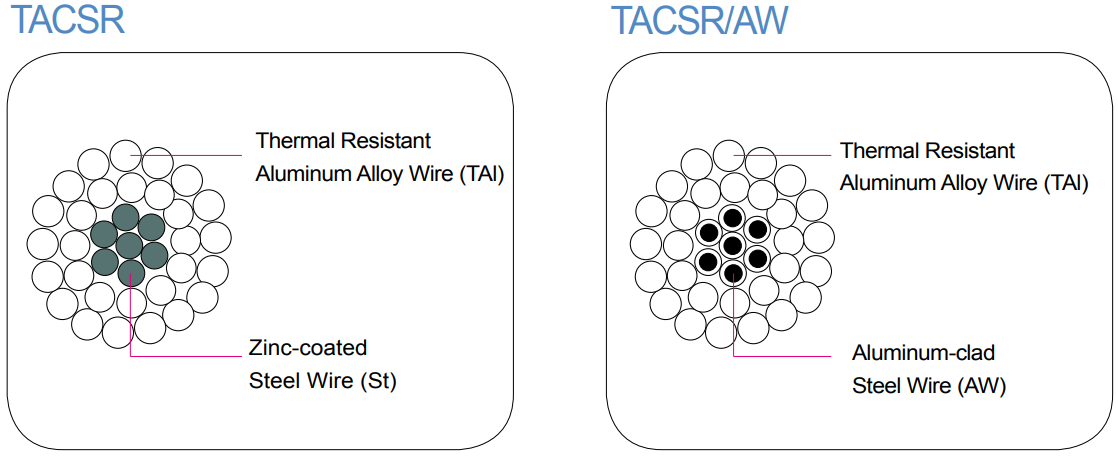

Galvanised steel core wire /Zinc-coated Steel Wire / Aluminum-clad Steel Wire(AW) - for ACSR

TACSR Conductors are very similar in construction to a conventional ACSR conductor but the EC Grade Aluminum wires are replaced with Hard Drawn Aluminum wires of Heat Resistant Aluminum Alloy (generally known as TAL ) . TACSR can be safely operated continuously above 150℃ enabling to pump more current through the conductor. Where there is a need to transmit higher power but restrictions on getting new power corridors approved, various Types of TAL conductors are one of the best creative solution options to utilities. Ability of the Zirconium doped aluminum alloy to maintain its electrical and mechanical properties at elevated temperatures makes these conductors a very cost effective solution in refurbishing the existing lines with enhanced capacity.

TACSR (/AW) is used for overhead electric power transmission lines. Big city, seaside district, moisture area etc.

• Core(St, AW): Zinc-coated Steel Wire / Aluminum-clad Steel Wire(AW) : 14% ~ 40% AW

• Conductor(TAI) : Thermal Resistant Aluminum Alloy Wire used for continuously allowable temperature up to 150℃

Features:

New aluminium alloys having high thermal resistance can carry 50%-60% more current than ACSR of the same size, while maximum sag and maximum working tension remains almost the same as that of ACSR.

● Can carry 50%-60% more current than ACSR of the same size.

● Higher capacity new lines can be built to deal with future demands.

TECHNICAL SPECIFICATIONS

PROPERTIES | TACSR (ACSR MOOSE EQUIVALENT | TACSR (ACSR ZEBRA EQUIVALENT) | TACSR (ACSR PANTHER EQUIVALENT) | |||

Typical factors | 3.53 mm | 0.1378 in | 3.18 mm | 0.1252 in | 3.00 mm | 0.1181 in |

Reference specifications | IEC 62004 | IEC 62004 | IEC 62004 | |||

Total cross section area | 596.99 mm2 | 0.9253 in2 | 484.25 mm2 | 0.7506 in2 | 261.50 mm2 | 0.4054 in2 |

Conductive wire | Al Zr ATI | Al Zr ATI | Al Zr ATI | |||

Core wire | Galvanized Steel | Galvanized Steel | Galvanized Steel | |||

Conductor diameter | 31.77 mm | 1.2508 in | 28.62 mm | 1.1268 in | 21.00 mm | 0.8268 in |

Weight | 2004 | 1346.6 | 1621 | 1089.3 | 972 | 653.2 |

kg/gm | Ibs/mile | kg/km | Ibs/mile | kg/km | Ibs/mile | |

Ultimate tensile strength | 16438 kg | 36239.54 lbs | 14407 kg | 31761.96 lbs | 10119 kg | 22308.55 lbs |

DC resistance at | 0.06 | 0.09 | 0.07 | 0.11 | 0.14 | 0.22 |

20°C temperature | 0/km | Q/mile | O/km | Q/mile | n/km | Q/mile |

Maximum operating temperature | 150°C | 302°F | 150°C | 302°F | 150°C | 302°F |

Current carrying capacity at maximum operating temperature | 1509 Amp | 1302 Amp | 831 Amp | |||

TACSR

Conductor Size

(mm2) | Stranding (Nos./mm) | Min. Breaking Load (kgf) | Reference | |||||||||||||

Cross-sectional Area (mm2) | Overall Diameter (mm) | Weight (kg/km) | DC Resistance at 20℃ (Ω/km) | Modulus of Elasticity (kgf/mm2) | Coefficient of Linear Expansion (10-6/℃) | Standard Length

(m) | Current Carrying Capacity (A) | |||||||||

TAl | ST | TAl | ST | Total | TAl | ST | TAl | ST | Total | |||||||

58 | 6/3.5 | 1/3.5 | 1,980 | 57.73 | 9.621 | 67.35 | 10.5 | 3.5 | 158.1 | 75.04 | 233.1 | 0.505 | 8,400 | 18.9 | 1,000 | 343 |

80 | 6/4.2 | 1/4.2 | 2,770 | 83.10 | 13.85 | 96.95 | 12.6 | 4.2 | 227.5 | 108.0 | 335.5 | 0.350 | 8,400 | 18.9 | 1,000 | 430 |

95 | 6/4.5 | 1/4.5 | 3,810 | 95.40 | 15.90 | 111.3 | 13.5 | 4.5 | 261.2 | 124.0 | 385.2 | 0.306 | 8,400 | 18.9 | 1,000 | 478 |

80 | 15/2.6 | 4/2.6 | 4,720 | 79.64 | 21.24 | 100.9 | 13.0 | 7.8 | 219.2 | 166.5 | 385.7 | 0.368 | 9,390 | 17.6 | 2,000 | 448 |

100 | 15/2.9 | 4/2.9 | 5,580 | 99.08 | 26.42 | 125.5 | 14.5 | 8.7 | 272.8 | 207.1 | 479.9 | 0.296 | 9,390 | 17.6 | 2,000 | 517 |

120 | 15/3.2 | 4/3.2 | 5,550 | 120.6 | 32.17 | 152.8 | 16.0 | 9.6 | 332.2 | 252.2 | 584.4 | 0.243 | 9,390 | 17.6 | 2,000 | 590 |

120 | 30/2.3 | 7/2.3 | 5,540 | 124.7 | 29.09 | 153.8 | 16.1 | 6.9 | 345.7 | 228.0 | 573.7 | 0.237 | 9,080 | 18.0 | 2,000 | 598 |

160 | 30/2.6 | 7/2.6 | 6,980 | 159.3 | 37.16 | 196.5 | 18.2 | 7.8 | 441.5 | 291.3 | 732.8 | 0.185 | 9,080 | 18.0 | 2,000 | 706 |

200 | 30/2.9 | 7/2.9 | 8,640 | 198.2 | 46.24 | 244.4 | 20.3 | 8.7 | 549.3 | 362.4 | 911.7 | 0.149 | 9,080 | 18.0 | 2,000 | 816 |

240 | 30/3.2 | 7/3.2 | 10,210 | 241.3 | 56.29 | 297.6 | 22.4 | 9.6 | 668.9 | 441.3 | 1,110 | 0.122 | 9,080 | 18.0 | 2,000 | 932 |

330 | 26/4.0 | 7/3.1 | 10,950 | 326.8 | 52.84 | 379.6 | 25.3 | 9.3 | 905.4 | 414.2 | 1,320 | 0.0904 | 8,360 | 19.0 | 2,000 | 1,128 |

410 | 26/4.5 | 7/3.5 | 13,910 | 413.4 | 67.35 | 480.8 | 28.5 | 10.5 | 1,145 | 527.9 | 1,673 | 0.0714 | 8,360 | 19.0 | 2,000 | 1,322 |

480 | 45/3.7 | 7/2.47 | 11,260 | 483.8 | 33.54 | 517.34 | 29.6 | 7.41 | 1336.1 | 262.9 | 1,599 | 0.0610 | 7,250 | 20.8 | 2,000 | 1,425 |

520 | 54/3.5 | 7/3.5 | 15,600 | 519.5 | 67.35 | 586.9 | 31.5 | 10.5 | 1,441 | 527.9 | 1,969 | 0.0569 | 7,990 | 19.5 | 1,600 | 1,504 |

610 | 54/3.8 | 7/3.8 | 18,350 | 612.4 | 79.38 | 691.8 | 34.2 | 11.4 | 1,698 | 622.2 | 2,320 | 0.0481 | 7,990 | 19.5 | 1,600 | 1,682 |

680 | 54/4.0 | 7/4.0 | 19,810 | 678.8 | 87.99 | 766.8 | 36.0 | 12.0 | 1,882 | 689.8 | 2,572 | 0.0436 | 7,990 | 19.5 | 1,600 | 1,797 |

680 | 45/4.4 | 7/2.9 | 15,580 | 684.5 | 46.24 | 730.7 | 35.1 | 8.7 | 1,898 | 362.4 | 2,260 | 0.0431 | 7,250 | 20.8 | 1,600 | 1,787 |

810 | 45/4.8 | 7/3.2 | 18,480 | 814.5 | 56.29 | 870.8 | 38.4 | 9.6 | 2,259 | 441.3 | 2,700 | 0.0363 | 7,250 | 20.8 | 1,600 | 2,004 |

1,160 | 84/4.2 | 7/4.2 | 27,830 | 1.163 | 96.95 | 1,260 | 46.2 | 12.6 | 3,236 | 759.8 | 3,996 | 0.0254 | 7,430 | 20.5 | 1,200 | 2,573 |

1,520 | 84/4.8 | 7/4.8 | 36,390 | 1.520 | 126.7 | 1,647 | 52.8 | 14.4 | 4,228 | 993.3 | 5,222 | 0.0195 | 7,430 | 20.5 | 1,200 | 3,035 |

TACSR/AW (20.3% Conductivity AW)

Conductor Size

(mm2) | Stranding (Nos./mm) | Min. Breaking Load (kgf) | Reference | ||||||||||

Cross-sectional Area (mm2) | Overall Diameter (mm) | Weight

(kg/km) | DC Resistance at 20℃ (Ω/km) | Modulus of Elasticity (kgf/mm2) | Coefficient of Linear Expansion (10-6/℃) | Standard Length

(m) | Current Carrying Capacity (A) | ||||||

TAl | AW | TAl | AW | TAl | AW | ||||||||

120 | 30/2.3 | 7/2.3 | 5,540 | 124.7 | 29.08 | 16.1 | 6.9 | 536.5 | 0.219 | 8,100 | 19.2 | 2,000 | 624 |

160 | 30/2.6 | 7/2.6 | 6,980 | 159.3 | 37.16 | 18.2 | 7.8 | 685.4 | 0.171 | 8,100 | 19.2 | 2,000 | 734 |

200 | 30/2.9 | 7/2.9 | 8,640 | 198.2 | 46.24 | 20.3 | 8.7 | 852.8 | 0.138 | 8,100 | 19.2 | 2,000 | 847 |

210 | 30/3.2 | 7/3.2 | 10,160 | 241.3 | 56.29 | 22.4 | 9.6 | 1,038 | 0.113 | 8,100 | 19.2 | 2,000 | 968 |

330 | 26/4.0 | 7/3.1 | 11,200 | 326.8 | 52.84 | 25.3 | 9.3 | 1,252 | 0.0856 | 7,620 | 20.0 | 2,000 | 1,159 |

410 | 26/4.5 | 7/3.5 | 14,230 | 413.4 | 67.35 | 28.5 | 10.5 | 1,587 | 0.0676 | 7,630 | 20.0 | 2,000 | 1,358 |

480 | 45/3.7 | 7/2.47 | 11,260 | 483.84 | 33.54 | 29.6 | 7.4 | 1,561 | 0.0595 | 6,910 | 21.5 | 2,000 | 1,437 |

520 | 54/3.5 | 7/3.5 | 15,920 | 519.5 | 67.35 | 31.5 | 10.5 | 1,883 | 0.0544 | 7,390 | 20.4 | 1,600 | 1,537 |

610 | 54/3.8 | 7/3.8 | 18,730 | 612.4 | 79.38 | 34.2 | 11.4 | 2,219 | 0.0461 | 7,330 | 20.4 | 1,600 | 1,717 |

680 | 45/4.4 | 7/2.9 | 15,580 | 684.5 | 46.24 | 35.1 | 8.7 | 2,201 | 0.0422 | 6,900 | 21.5 | 1,600 | 1,805 |

810 | 45/4.8 | 7/3.2 | 18,730 | 814.5 | 56.29 | 38.4 | 9.6 | 2,628 | 0.0354 | 6,910 | 21.5 | 1,600 | 2,028 |

950 | 84/3.8 | 7/3.8 | 23,780 | 952.6 | 79.38 | 41.8 | 11.4 | 3,170 | 0.0302 | 7,030 | 21.2 | 1,200 | 2,292 |

1,160 | 84/4.2 | 7/4.2 | 28,720 | 1,163 | 96.95 | 46.2 | 12.6 | 3,872 | 0.0247 | 7,030 | 21.2 | 1,200 | 2,606 |

1,520 | 84/4.8 | 7/4.8 | 37,520 | 1,520 | 126.7 | 52.8 | 14.4 | 5,060 | 0.0189 | 7,030 | 21.2 | 1,200 | 3,075 |

TACSR/AW (23% Conductivity AW)

Conductor Size

(mm2) | Stranding (Nos./mm) | Min. Breaking Load (kgf) | Reference | ||||||||||

Cross-sectional Area (mm2) | Overall Diameter (mm) | Weight

(kg/km) | DC Resistance at 20℃ (Ω/km) | Modulus of Elasticity (kgf/mm2) | Coefficient of Linear Expansion (10-6/℃) | Standard Length

(m) | Current Carrying Capacity (A) | ||||||

TAl | AW | TAl | AW | TAl | AW | ||||||||

120 | 30/2.3 | 7/2.3 | 7/2.3 | 124.7 | 29.08 | 16.1 | 6.9 | 528.9 | 0.217 | 7,980 | 19.4 | 2,000 | 625 |

160 | 30/2.6 | 7/2.6 | 7/2.6 | 159.3 | 37.16 | 18.2 | 7.8 | 675.7 | 0.170 | 7,980 | 19.4 | 2,000 | 736 |

200 | 30/2.9 | 7/2.9 | 7/2.9 | 198.2 | 46.24 | 20.3 | 8.7 | 840.7 | 0.136 | 7,980 | 19.4 | 2,000 | 854 |

210 | 30/3.2 | 7/3.2 | 7/3.2 | 241.3 | 56.29 | 22.4 | 9.6 | 1,024 | 0.112 | 7,980 | 19.4 | 2,000 | 973 |

330 | 26/4.0 | 7/3.1 | 7/3.1 | 326.8 | 52.84 | 25.3 | 9.3 | 1,238 | 0.085 | 7,540 | 20.2 | 2,000 | 1,163 |

410 | 26/4.5 | 7/3.5 | 7/3.5 | 413.4 | 67.35 | 28.5 | 10.5 | 1,570 | 0.0671 | 7,550 | 20.2 | 2,000 | 1,363 |

480 | 45/3.7 | 7/2.47 | 7/2.47 | 483.84 | 33.54 | 29.6 | 7.4 | 1,550 | 0.0592 | 6,880 | 20.6 | 2,000 | 1,441 |

520 | 54/3.5 | 7/3.5 | 7/3.5 | 519.5 | 67.35 | 31.5 | 10.5 | 1,865 | 0.0541 | 7,330 | 20.6 | 1,600 | 1,541 |

610 | 54/3.8 | 7/3.8 | 7/3.8 | 612.4 | 79.38 | 34.2 | 11.4 | 2,198 | 0.0458 | 7,320 | 20.6 | 1,600 | 1,722 |

680 | 45/4.4 | 7/2.9 | 7/2.9 | 684.5 | 46.24 | 35.1 | 8.7 | 2,189 | 0.0420 | 6,860 | 21.6 | 1,600 | 1,809 |

810 | 45/4.8 | 7/3.2 | 7/3.2 | 814.5 | 56.29 | 38.4 | 9.6 | 2,613 | 0.0353 | 6,880 | 21.6 | 1,600 | 2,031 |

950 | 84/3.8 | 7/3.8 | 7/3.8 | 952.6 | 79.38 | 41.8 | 11.4 | 3,149 | 0.0300 | 6,980 | 21.3 | 1,200 | 2,299 |

1,160 | 84/4.2 | 7/4.2 | 7/4.2 | 1,163 | 96.95 | 46.2 | 12.6 | 3,847 | 0.0246 | 6,980 | 21.3 | 1,200 | 2,611 |

1,520 | 84/4.8 | 7/4.8 | 7/4.8 | 1,520 | 126.7 | 52.8 | 14.4 | 5,027 | 0.0189 | 6,980 | 21.3 | 1,200 | 3,075 |

*Describe Your Buying Requirements in Detail