One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Copper Clad Steel Strand Wire Manufacturer in China

Copper clad steel ground wire can be used as earthing pole for electrical power industry. Much cost can be saved by using this newly-developed product for grounding.It is really the best choice for grounding system.

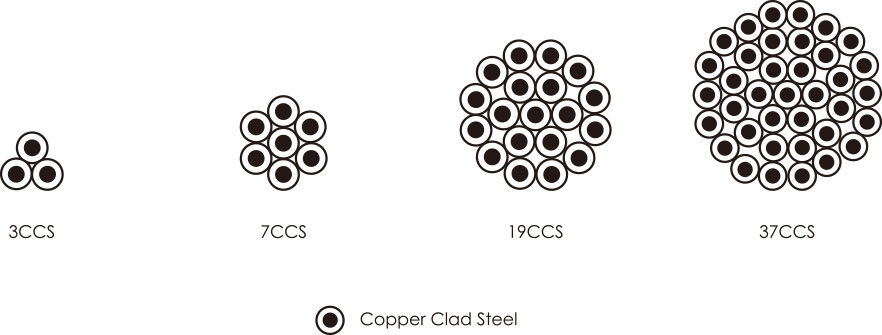

Copper-clad steel strand wires are made of a certain number of copper-clad steel single wires. Concentric-lay-stranded, 30% and 40% conductivity, conductors made from round copper-clad steel wires for electrical purposes. As ground wire for electrical power systems, telephone and CATV drop wire, tracer wire, and catenary wire for electrified railroads. Available in high strength (HS), extra-high strength (EHS), or dead soft annealed (DSA) tempers.

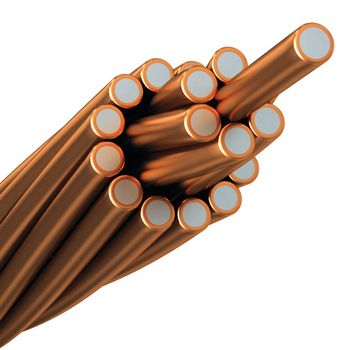

Copper Clad Steel (CCS) is a composite conductor material containing a low carbon steel core surrounded by copper. The copper provides the electrical conductivity and the steel contributes strength to the conductor. The most common grade of CCS used for electrical conductors has a nominal 40% IACS electrical conductivity. CCS is suitable for applications where high strength and medium conductivity are required. Copper Clad Steel is also suited for high frequency signal applications since high frequency currents travel mainly in the outer skin of a conductor.

CCS is available bare or plated with silver, nickel or tin.

Stranded bare copper-clad steel wire manufacturer are widely used in lightning protection and grounding in high-frequency coaxial cables, steel network communications, electrified railways, subway light rails, railways, airports, network communications and other places.

Copper Clad steel wire and strand combines the electrical characteristics of copper with the mechanical properties of steel. Often used for buried ground grid systems, overhead ground wire and messenger wire, it can resist mechanical damage during installation, as well as electrical damage during a fault condition. Copper Clad steel has virtually no scrap value, and is extremely difficult to cut with traditional wire and cable cutting tools, greatly reducing the potential of theft.

Copper Clad Steel Strand Wire

1. Application

It is widely applied in power transmission line, electricity line and other fields.

2. It is composed of pure copper layer and steel core.

3. Advantages

● Copper Clad Steel Wire pure electrolytic copper cable conductors for a variety of applications

● Stranded grounded conductor cut into standard lengths for easy field installation

● Optimized sizes to the most efficient electrical conductivity

● Good conductivity, and long use life.

Get quote by email: info@qingzhou-cable.com

Copper Clad Steel Wire (CCS)

1. Application

It is used in frequency coaxial cable, messenger wire, telephone drop-wire and distribution wire;

It is used as the lead-wire for electronics, carrying wire for railroad and wire for power transmission;

It is used in bind wire, jewellery chain, piano string cover and pipe insulation wire.

2. CCS wire is formed through electroplating method(taking steel wire as the core and depositing the copper layer evenly on the surface of the steel core) and cladding method (Cladding planished copper stripe concentrically on the outer surface of the steel core).

3. Advantages

Anti-corrosion. As the copper-coated steel wire has a steel core with a uniform copper coating, it is highly resistant to corrosion in air. If the wire is of large diameter and is used as aerial line, bare wire can be used without PVC covered.

Small signal transmission decay. There is skin effect in the transmission of high frequency communication signal. The electric signal is transmission signal. The electric signal is transmitted in the outer copper layer. The transmission decay of copper-coated steel wire is as small as pure copper wire. 50% to 70% copper can be saved using copper-coated steel wire instead of pure copper wire.

High strength and low density. Since the steel core can enhance the strength of copper-coated steel wire, and the density of steel is lower than that of copper, the size of suspension steel wire can be reduced by using copper-coated steel wire as aerial line.

It can be divided into six types in accordance with the conductivity,

15% CCS, 18% CCS, 21% CCS, 25% CCS and 40% CCS.

Cross-section area( mm2) | Single Wire Diameter( mm ) | Nos | Outer Diameter( mm ) | Reference Weight( kg/km ) |

16 | 1.70 | 7 | 5.10 | 130 |

25 | 2.12 | 7 | 6.36 | 200 |

35 | 2.52 | 7 | 7.50 | 280 |

50 | 3.00 | 7 | 9.00 | 410 |

70 | 3.50 | 7 | 10.60 | 590 |

95 | 2.52 | 19 | 12.60 | 780 |

120 | 2.80 | 19 | 14.00 | 980 |

150 | 3.15 | 19 | 15.80 | 1230 |

185 | 3.50 | 19 | 17.50 | 1520 |

240 | 4.00 | 19 | 20.00 | 1970 |

300 | 3.15 | 37 | 23.50 | 2460 |

400 | 3.70 | 37 | 3280 |

Physical Properties

HARD DRAWN | SOFT | |

Tensile | 110 ksi | 45 ksi |

Elongation | 1% | 10% |

Electrical Conductivity | 39% IACS* @ 68°F | 39% IACS* @ 68°F |

Electrical Resistivity | 26.45 cir mil ohm/ft @ 68°F | 26.45 cir mil ohm/ft @ 68°F |

Melting Point | --- | --- |

Density | 0.294 lbs/in³ | 0.294 lbs/in³ |

Thermal Coefficient of Resistance | 0.00210 Per °F | 0.00210 Per °F |

19-Strand Concentric Constructions

BARE CCS (40%) - HARD TEMPER | ||||||

AWG | CONST | DIAMETER (inch) | RESIST | WEIGHT | BREAK STRG | |

MIN | MAX | MAX | MAX | MIN | ||

18 | 19/30 | 0.0495 | 0.0505 | 14.5 | 5.47 | 160.9 |

20 | 19/32 | 0.0395 | 0.0405 | 22.7 | 3.51 | 102.4 |

22 | 19/34 | 0.0310 | 0.0320 | 37.0 | 2.20 | 63.1 |

24 | 19/36 | 0.0245 | 0.0255 | 58.8 | 1.39 | 39.4 |

26 | 19/38 | 0.0195 | 0.0205 | 92.9 | 0.899 | 25.0 |

28 | 19/40 | 0.0150 | 0.0160 | 157.1 | 0.548 | 14.8 |

BARE CCS (40%) - SOFT TEMPER | ||||||

AWG | CONST | DIAMETER (inch) | RESIST | WEIGHT | BREAK STRG | |

MIN | MAX | MAX | MAX | MIN | ||

18 | 19/30 | 0.0495 | 0.0505 | 14.5 | 5.47 | 65.8 |

20 | 19/32 | 0.0395 | 0.0405 | 22.7 | 3.51 | 41.9 |

22 | 19/34 | 0.0310 | 0.0320 | 37.0 | 2.20 | 25.8 |

24 | 19/36 | 0.0245 | 0.0255 | 58.8 | 1.39 | 16.1 |

26 | 19/38 | 0.0195 | 0.0205 | 92.9 | 0.899 | 10.2 |

28 | 19/40 | 0.0150 | 0.0160 | 157.1 | 0.548 | 6.04 |

7-Strand Constructions

BARE CCS (40%) - HARD TEMPER | ||||||

AWG | CONST | DIAMETER (inch) | RESIST | WEIGHT | BREAK STRG | |

MIN | MAX | MAX | MAX | MIN | ||

22 | 7/30 | 0.0297 | 0.0303 | 39.1 | 2.01 | 59.2 |

24 | 7/32 | 0.0237 | 0.0243 | 61.1 | 1.28 | 37.7 |

26 | 7/34 | 0.0186 | 0.0192 | 99.3 | 0.803 | 23.2 |

28 | 7/36 | 0.0147 | 0.0153 | 159.0 | 0.510 | 14.5 |

30 | 7/38 | 0.0117 | 0.0123 | 250.1 | 0.328 | 9.20 |

32 | 7/40 | 0.0090 | 0.0096 | 424.1 | 0.201 | 5.44 |

BARE CCS (40%) - SOFT TEMPER | ||||||

AWG | CONST | DIAMETER (inch) | RESIST | WEIGHT | BREAK STRG | |

MIN | MAX | MAX | MAX | MIN | ||

22 | 7/30 | 0.0297 | 0.0303 | 39.1 | 2.01 | 24.2 |

24 | 7/32 | 0.0237 | 0.0243 | 61.1 | 1.28 | 15.4 |

26 | 7/34 | 0.0186 | 0.0192 | 99.3 | 0.803 | 9.50 |

28 | 7/36 | 0.0147 | 0.0153 | 159.0 | 0.510 | 5.94 |

30 | 7/38 | 0.0117 | 0.0123 | 250.1 | 0.328 | 3.76 |

32 | 7/40 | 0.0090 | 0.0096 | 424.1 | 0.201 | 2.23 |

Single End Constructions

NICKEL PLATED CCS (40%) - HARD/SOFT | ||||||||

AWG | STD | DIAMETER (inch) | RESIST | WEIGHT | BREAK STRG | BREAK STRG | ||

NOM | MIN | MAX | MAX | MAX | MIN | MIN | ||

30 | 2 | 0.0101 | 0.0099 | 0.0103 | 281.1 | 0.298 | 8.47 | 3.46 |

31 | 4 | 0.0090 | 0.0088 | 0.0092 | 363.4 | 0.238 | 6.69 | 2.74 |

32 | 4 | 0.0081 | 0.0079 | 0.0083 | 450.9 | 0.194 | 5.39 | 2.21 |

33 | 4 | 0.0071 | 0.0069 | 0.0073 | 574.2 | 0.154 | 4.23 | 1.73 |

34 | 4 | 0.0064 | 0.0062 | 0.0066 | 732.0 | 0.121 | 3.32 | 1.36 |

35 | 4 | 0.0057 | 0.0055 | 0.0059 | 930.2 | 0.0966 | 2.61 | 1.07 |

36 | 4 | 0.0051 | 0.0049 | 0.0053 | 1,172 | 0.0779 | 2.07 | 0.849 |

37 | 7 | 0.0046 | 0.0044 | 0.0048 | 1,501 | 0.0639 | 1.67 | 0.684 |

38 | 7 | 0.0041 | 0.0039 | 0.0043 | 1,911 | 0.0513 | 1.31 | 0.538 |

39 | 7 | 0.0036 | 0.0034 | 0.0038 | 2,514 | 0.0401 | 0.999 | 0.409 |

40 | 7 | 0.0032 | 0.0030 | 0.0034 | 3,230 | 0.0321 | 0.778 | 0.318 |

SILVER PLATED CCS (40%) | ||||||||

AWG | STD | DIAMETER (inch) | RESIST | WEIGHT | BREAK STRG | BREAK STRG | ||

NOM | MIN | MAX | MAX | MAX | MIN | MIN | ||

30 | 3 | 0.0100 | 0.0099 | 0.0101 | 269.9 | 0.288 | 8.47 | 3.46 |

31 | 3 | 0.0089 | 0.0088 | 0.0090 | 341.6 | 0.229 | 6.69 | 2.74 |

32 | 4 | 0.0080 | 0.0079 | 0.0081 | 423.8 | 0.185 | 5.39 | 2.21 |

33 | 4 | 0.0071 | 0.0070 | 0.0072 | 539.8 | 0.147 | 4.23 | 1.73 |

34 | 4 | 0.0063 | 0.0062 | 0.0064 | 688.1 | 0.116 | 3.32 | 1.36 |

35 | 5 | 0.0056 | 0.0055 | 0.0057 | 874.4 | 0.0921 | 2.61 | 1.07 |

36 | 5 | 0.0050 | 0.0049 | 0.0051 | 1,102 | 0.0739 | 2.07 | 0.849 |

37 | 6.1 | 0.0045 | 0.0044 | 0.0046 | 1,366 | 0.0602 | 1.67 | 0.684 |

38 | 6.1 | 0.0040 | 0.0039 | 0.0041 | 1,739 | 0.0479 | 1.31 | 0.538 |

39 | 8 | 0.0035 | 0.0034 | 0.0036 | 2,288 | 0.0370 | 0.999 | 0.409 |

40 | 8 | 0.0031 | 0.0030 | 0.0032 | 2,939 | 0.0293 | 0.778 | 0.318 |

Qingzhou Cable offers the widest range of world-class wires and cable from hairline to the largest requirement of virtually all essential industries.

Send the details by email for price list now and product catalogue

info@qingzhou-cable.com

Pre:Conductor Bare ACSR Manufacturer & Supplier from China for Philippine Market

Next:Multi-Pair 20 AWG to 12 AWG Cable Manuafcturer from China

*Describe Your Buying Requirements in Detail