One-stop Solution for Wire and Cable

Email:info@qingzhou-cable.com

WhatsApp/WeChat/Skype/Phone:+8618625503172

WhatsApp/WeChat/Skype/Phone:+8618625503172

Email:

info@qingzhou-cable.com

Email:

info@qingzhou-cable.com

Tel:

+8618625503172

Tel:

+8618625503172

Fax:

+8618625503172

Fax:

+8618625503172

Skype:

+8618625503172

Skype:

+8618625503172

Photovoltaic Solar (PV) Cables

62930 IEC 131 1500VDC

2 PFG 1169 PV1-F 1x4mm

EN50618 H1Z2Z2-K 1x4mm2 1500VDC

UL4703 PV wire

Aluminum Solar Cabel PV1500DC-AL

2000V Solar DC Cable PV2000DC-TC5

2000V Aluminum Solar Cable PV2000DC-AL5

Flat Twin Core 2X4mm2 Solar PV Cable

Solar Battery Cable ES-A09VV-F

Solar cables can be copper or aluminum and are generally protected by a Rubber or plastic sheath to withstand bad weather and UV rays.

Manufactured in accordance with various British and International Standards, our PV cables include EN50618 standard, under the harmonised reference H1Z2Z2-K. They are for applications typical of solar farms and rooftop solar installations, providing the interconnection of photovoltaic power generation systems and the solar panel arrays. This robust outdoor cable range is designed to withstand severe environmental conditions and degradation from UV light exposure.

We supply solar aluminium cables and low voltage DC combiner cables to run from the panels to the inverter / transformer, as well as the cables for the wider grid integration and connection, both on private networks contestable connections.

The mainly products include Tinned alloy PV cable (PVENER-V1), tinned copper PV cable (H1Z2Z2-K / PV1-F / PV WIRE).

PV cables are manufactured according to the following standards: EN50618, 2 PFG 1169, IEC62930, UL4703 or 2 PFG 2642.

We entered the solar industry in 2006. In the initial stage of solar PV industry, we participated in product certification under a series of standards, such as 2 PFG 1161, DIN V VDE V 0126-3, EN50521, 2 PFG 1169, etc. Now we have formed a complete R & D, production and sales service system.

QZ Cable produces different types of photovoltaic cables, You can contact us to find out the latest cable prices.

Explore our selection of high-performance solar cables designed for durability and efficiency in solar power installations.

HNQZ Cable is one of the most trusted brands in cable and wires. It was created with an aim to cater to high quality solar cables in market. Through times we have catered to products that required high-end INNOVATION and RESEARCH.

HNQZ Cable’s Solar Cables are a step towards creation of environment friendly cables for development of electricity through solar-power. It is our effort to take part in energy conservation. Our range of PV-cables (also known as SOLAR CABLES) are more ADAPTIVE, more ROBUST, RUGGED and more VERSATILE than ever before. These cables are made in compliance standards such as RoHS and CE Certification.

HNQZ Photovoltaic Solar (PV) Cables are exclusively made for applications in photovoltaic power systems. A solar cable interconnects solar panels and other electrical components of photovoltaic system. These Solar cables are designed to be UV & Ozone resistant, Chemical and Oil resistant, with excellent FR Properties, propagates smoke with low Capacity when burned with external source and contains absolutely ZERO or Low halogen. This cable can survive extreme weather conditions. It can be used within a large temperature range and are generally laid outside.These cables can be installed at indoor in hazard area, in explosion areas, in industry and in agriculture.

LIFETIME RELIABILITY: Lasts up to: 30 years even under tough external conditions.

OUTDOOR DURABILITY: Resists extreme temperatures (-40°C to 120°C maximum at the core) and Ozone resistant.

UV RESISTANCE: Full Protection against ultraviolet rays.

HALOGEN-FREE: Low smoke emission & Low toxicity / Corrosivity during fire.

PROPERTIES AGAINST FIRE: Flame Retardant, Fire Retardant.

FLEXIBILITY AND STRIP ABILITY: For fast and easy Installation.

FULLY RECYCLABLE: In accordance with new environmental regulations.

Easy Installation with color identification (blue, red).

Suitable to common connector types.

Annealed Bunched Flexible Copper conductor with ETP Copper with 99.97% purity and 101% conductivity

Tinned copper bunched flexible conductor with ETP Copper with 99.97% purity and 101% conductivity

Double insulated Cross-linkable Fire retardant Low Smoke Zero halogen with conductor temp. Rating 120°C

Double insulated Flexible insulation with Fire retardant Low Smoke Zero halogen with conductor temp. Rating 105°C

Double insulated:

First layer Cross Linkable Thermo-set Polymer with Conductor Temperature rating 90°C

Second layer UV Stabilized FRLS-H Sheath

Insulation: Halogen-free, cross-linked flame retardant compound (HFFR).

Outer Sheath: Black Halogen-free, cross-linked flame retardant compound (HFFR).

Single cable according to DIN VDE 0482 Part 332-1-2, DIN EN 60332-1-2

Multiple cable according to DIN VDE 0480 Part 266-2-1, DIN EN 50305-9

Low smoke emission according to DIN VDE 0482 part 268-1& 2

DIN EN 61034 & DIN EN 50268-2 (light transmittance<70%)

Corrosively according to DIN EN 50267-2-2

Toxicity according ti DIN EN 50305

The components of a PV cable are assembled to ensure durability, flexibility, and resistance to environmental factors. These components include:

Conductor: The conductor, the heart of the cable, is responsible for carrying electrical current. PV cables typically use copper conductors for their superior conductivity, flexibility, and durability, though aluminum can be used as a more cost-effective option.

Insulation: The conductor is surrounded by insulation, which prevents short circuits and electrical shocks. PV cables utilize specialized insulation materials like cross-linked polyethylene (XLPE), ethylene propylene rubber (EPR), or thermoplastic elastomers (TPE). These materials offer excellent electrical insulation, as well as resistance to intense heat, UV radiation, and extreme weather conditions.

Jacket/Sheath: The PV cable's outer jacket (or sheath) provides essential protection against mechanical damage, abrasion, moisture, sunlight (UV radiation), and other environmental factors. This jacket is typically made from durable polymers like polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), or halogen-free flame-resistant materials.

Filler Material: Some PV cables may include filler materials such as non-conductive powders or fibers to improve the cable’s flexibility, reduce stress on the conductor, and enhance the overall mechanical properties of the cable.

Tape/Wrapping: In some cases, additional layers of tape or wrapping may be applied to the conductor or insulation to provide further protection against moisture ingress, mechanical damage, or abrasion.

The specific materials used in PV cables depend on the application, environmental conditions, regulatory requirements, and industry standards. It’s crucial to choose cables with materials designed to withstand the harsh outdoor conditions faced by solar energy systems.

PV cables are essential components of the solar energy industry, specifically designed for use in photovoltaic systems that convert sunlight into electricity. Here are some specific applications where PV cables are vital:

1. Solar Power Plants: Solar power plants, also known as solar parks or solar farms, are large-scale facilities that harness the sun's energy and convert it into usable electricity.

2. Residential Solar Installations: Residential solar installations refer to the process of installing solar panels on a home's roof or property to generate clean, renewable electricity.

3. Commercial and Industrial Solar Installations: Commercial and industrial solar installations refer to solar power systems designed to generate electricity for businesses, institutions, factories, and other non-residential facilities.

4. Off-Grid and Remote Solar Systems: Off-grid and remote solar systems are designed to provide electricity to homes, businesses, and communities that are not connected to the main power grid. These systems are self-sufficient, relying entirely on solar energy and battery storage to meet power needs.

5. Solar Street Lighting: Solar street lights are independent lighting systems that harness the sun's energy to provide illumination for streets, walkways, parks, and other public areas.

6. Solar Water Pumping: Solar water pumping systems use the power of the sun to pump water from wells, boreholes, rivers, or other sources. They provide a reliable and sustainable water supply for various applications, especially in remote or off-grid areas.

Solar Energy and Battery Storage Solutions

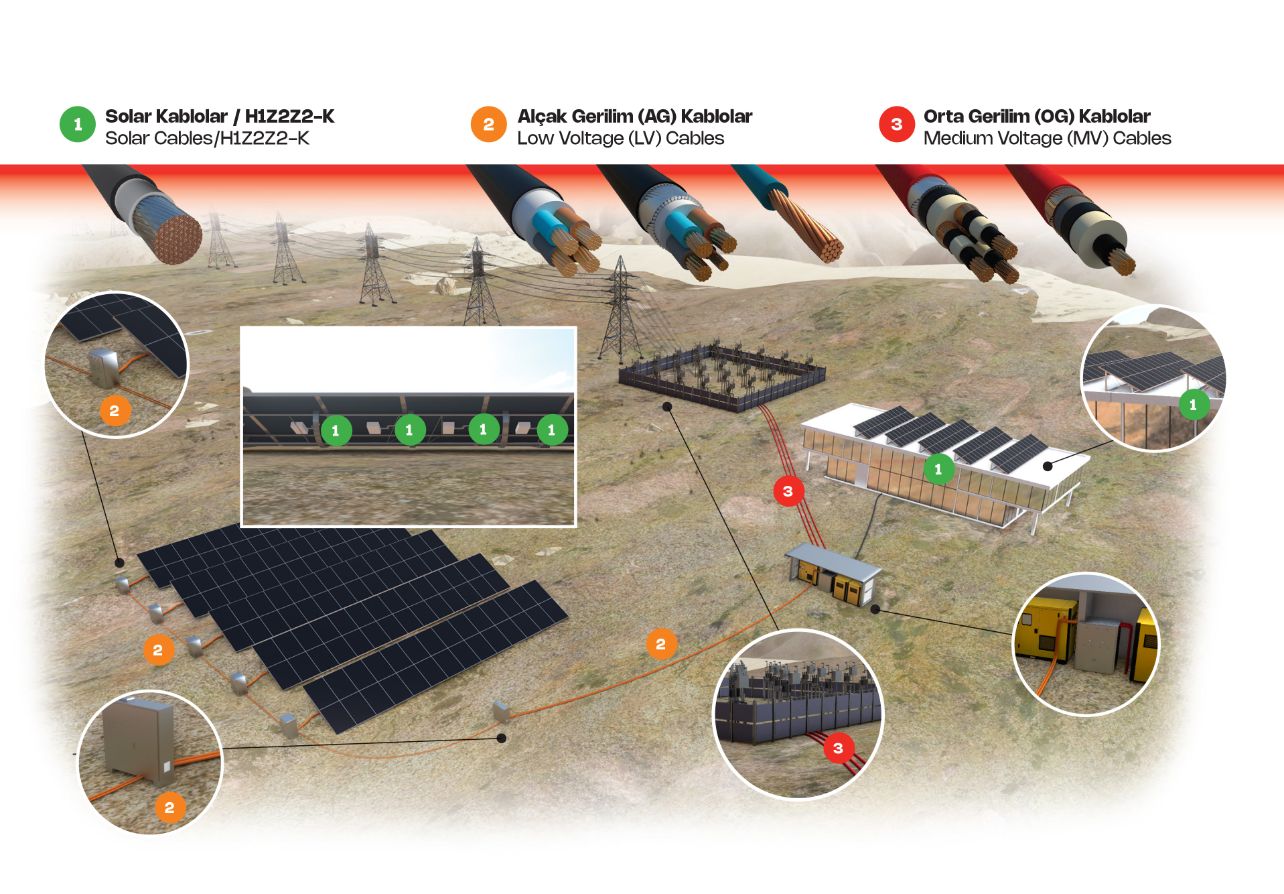

Increasingly, solar projects are accompanied by BESS Energy Storage solutions to optimise and balance usage. Our expertise in providing cable solutions for integrated systems aids large-scale installations. Additionally, integrating into the wider grid network means we also supply a wide range of bare copper conductors, low voltage, and medium voltage cables connecting the solar installation to substations and to the power grid, including utility DNO-approved cables.

Our solar cables can be found on some of the largest and most prestigious solar farms across the Uzbekistan, including BESS Project Our complete solar cable solutions have also contributed to the completion of some of Africa’s largest solar generation plants.

*Describe Your Buying Requirements in Detail